A Case Study Addendum: How BYD Became A Leader In EV Battery Technology

Table of Contents

BYD's Vertical Integration Strategy

BYD's success in EV battery technology isn't solely down to innovation; it's also a masterful display of strategic vertical integration. Controlling every stage of the EV supply chain, from raw material sourcing to final vehicle assembly, has provided BYD with a significant competitive edge. This control minimizes reliance on external suppliers, reduces costs, and ensures consistent quality.

Control of Raw Materials

Securing a stable supply of raw materials is crucial for any battery manufacturer. BYD has proactively addressed this challenge through several key strategies:

- Strategic Partnerships: BYD has forged partnerships with mining companies globally, securing access to vital raw materials like lithium, cobalt, and manganese, essential components in lithium-ion batteries. These partnerships guarantee a consistent supply, mitigating supply chain disruptions and price volatility.

- Investment in Processing Facilities: Rather than solely relying on external suppliers for processed materials, BYD has invested heavily in its own processing facilities. This vertical integration allows for greater control over quality, cost, and the entire production process.

- Vertical Integration Advantages: This approach provides a significant competitive advantage, reducing dependence on external factors and enhancing price competitiveness. It also allows for quicker responses to market fluctuations and evolving technological needs.

In-House Battery Production

BYD's massive battery manufacturing capacity is a cornerstone of its success. The company operates numerous gigafactories, employing advanced manufacturing techniques to produce batteries at scale.

- Gigafactories: BYD's network of gigafactories represents a massive investment in production capacity, ensuring it can meet the ever-growing global demand for EV batteries.

- Advanced Manufacturing Techniques: BYD utilizes cutting-edge manufacturing techniques to optimize efficiency and reduce production costs. This focus on automation and streamlined processes ensures high-quality batteries are produced at a competitive price.

- Economies of Scale: The sheer scale of BYD's production allows it to benefit significantly from economies of scale, further reducing costs per unit and strengthening its competitive position in the market.

- Reduced Reliance on External Suppliers: In-house production minimizes dependence on external battery suppliers, safeguarding against potential supply chain bottlenecks and ensuring consistent production.

Seamless Integration with Vehicle Manufacturing

The integration of battery production and vehicle manufacturing is a key differentiator for BYD. This synergy allows for optimal design and performance, leading to superior EVs.

- Improved Quality Control: Having complete control over the entire process from battery cell to finished vehicle allows for tighter quality control, leading to more reliable and higher-performing EVs.

- Faster Product Development Cycles: Seamless integration streamlines the product development process, allowing BYD to quickly introduce new models and technologies to the market.

- Cost Optimization: The vertical integration model allows for optimized cost management across the entire supply chain, making BYD's EVs more competitively priced.

Technological Innovation: The Blade Battery and Beyond

BYD's technological prowess is perhaps best exemplified by its revolutionary Blade Battery. This technology has significantly advanced EV battery performance and safety.

The Blade Battery Revolution

The Blade Battery represents a significant departure from traditional cylindrical or prismatic battery cell designs. Its unique features offer several key advantages:

- Higher Energy Density: The Blade Battery boasts a higher energy density compared to traditional designs, allowing for a greater driving range on a single charge.

- Improved Safety Features: Its design inherently improves safety, reducing the risk of thermal runaway and enhancing overall battery safety.

- Space Optimization: The blade-like form factor allows for optimal space utilization within the vehicle, maximizing interior space and improving vehicle design flexibility.

- Cost Advantages: BYD's manufacturing expertise has resulted in a cost-effective production process for the Blade Battery, making it a commercially viable solution.

- LFP Chemistry Benefits: The Blade Battery utilizes Lithium Iron Phosphate (LFP) chemistry, known for its inherent safety and cost-effectiveness, further enhancing its appeal.

Ongoing Research and Development

BYD's commitment to innovation extends beyond the Blade Battery. The company continues to invest heavily in R&D, exploring next-generation battery technologies.

- Solid-State Batteries: BYD is actively researching and developing solid-state battery technology, which promises even higher energy density, improved safety, and faster charging times.

- Advancements in LFP Chemistry: Ongoing research focuses on further improving the performance and energy density of LFP batteries, maximizing their cost-effectiveness and environmental benefits.

- Improved Battery Management Systems: BYD is continually enhancing its battery management systems (BMS) to optimize battery performance, extend battery life, and enhance safety features.

Market Leadership and Global Expansion

BYD's success isn't confined to technological innovation; it's also a story of market dominance and global expansion.

Dominance in the Chinese EV Market

BYD has established itself as a leading player in the rapidly growing Chinese EV market. Several factors contribute to this success:

- Strong Brand Recognition: BYD has cultivated a strong brand reputation in China, synonymous with quality, reliability, and innovation.

- Extensive Sales Network: A wide-reaching sales and service network ensures easy access to BYD's EVs for consumers across China.

- Competitive Pricing: BYD's efficient production and vertical integration allow it to offer competitively priced EVs.

- Government Support: Favorable government policies promoting electric vehicles in China have also played a role in BYD's success.

Global Market Penetration

BYD is actively expanding its presence into international markets, pursuing global growth through strategic initiatives:

- Partnerships with International Distributors: BYD is collaborating with established international distributors to expand its reach into new markets.

- Establishment of Overseas Manufacturing Facilities: The company is setting up manufacturing facilities outside China to reduce reliance on exports and cater to local market needs.

- Adaptation to Local Market Needs: BYD is adapting its vehicle designs and features to meet the specific requirements and preferences of different international markets.

Conclusion

BYD's rise to become a leader in EV battery technology is a testament to its strategic vision, technological innovation, and commitment to sustainable solutions. Its vertical integration strategy, coupled with groundbreaking battery technology like the Blade Battery, has given it a significant competitive advantage. The company’s ongoing investment in R&D and expansion into global markets further solidify its position as a key player in the electric vehicle revolution. By leveraging its expertise in EV battery technology and continuing to innovate, BYD is poised for continued growth and success. Learn more about BYD's advancements in EV battery technology and its impact on the future of sustainable transportation.

Featured Posts

-

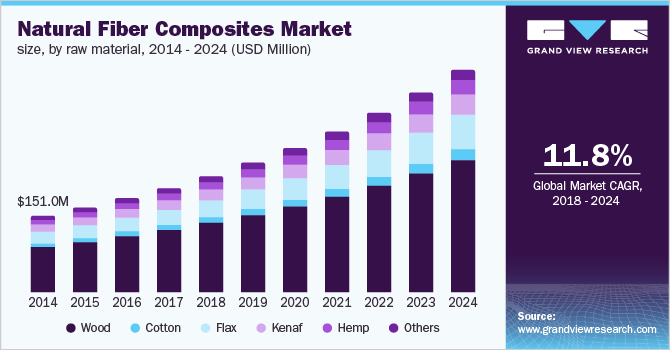

Global Natural Fiber Composites Market Outlook To 2029

May 13, 2025

Global Natural Fiber Composites Market Outlook To 2029

May 13, 2025 -

Betting On Natural Disasters The La Wildfires And The Changing Times

May 13, 2025

Betting On Natural Disasters The La Wildfires And The Changing Times

May 13, 2025 -

10 Aktori Koito Sa Spasili Khora Inspiriraschi Istorii

May 13, 2025

10 Aktori Koito Sa Spasili Khora Inspiriraschi Istorii

May 13, 2025 -

Trumps Plan To Track Undocumented Immigrants Via Irs Data Approved By Judge

May 13, 2025

Trumps Plan To Track Undocumented Immigrants Via Irs Data Approved By Judge

May 13, 2025 -

Gibraltar Blockchain Event Coinsilium Group And Forza Partnership

May 13, 2025

Gibraltar Blockchain Event Coinsilium Group And Forza Partnership

May 13, 2025