Advanced Techniques For Automated Visual Inspection Of Lyophilized Vials

Table of Contents

High-Resolution Imaging for Enhanced Defect Detection

High-resolution imaging is fundamental to effective automated visual inspection of lyophilized vials. The ability to identify subtle defects directly impacts product quality and patient safety. Several key aspects contribute to superior defect detection:

-

Superior Camera Technology and Illumination: High-resolution cameras, coupled with optimized lighting techniques, are crucial. Advanced cameras capture minute details often missed by the human eye or standard systems. Specialized lighting, such as structured illumination or multispectral lighting, can highlight subtle cracks, particulate matter, or other imperfections within the lyophilized cake or vial itself. This ensures comprehensive coverage during the automated inspection.

-

Wavelength Optimization: Utilizing various wavelengths of light dramatically improves defect visibility. For instance, near-infrared (NIR) light can penetrate the lyophilized material better than visible light, revealing internal defects that would otherwise go unnoticed. Different wavelengths can also enhance the contrast of specific defects, facilitating easier identification by the image processing algorithms.

-

Advanced Imaging Modalities: Techniques like confocal microscopy offer three-dimensional (3D) analysis of the vial contents. This allows for a detailed examination of the lyophilized cake's structure, revealing inconsistencies and potential defects that 2D imaging might miss. This 3D analysis is invaluable for a thorough assessment of the product's integrity.

-

Defect Types Detected: High-resolution imaging, aided by appropriate lighting and advanced techniques, effectively detects a wide array of defects, including: cracks in the lyophilized cake, particulate contamination, vial imperfections (e.g., scratches, chips), variations in fill volume, and discoloration. This comprehensive detection minimizes the risk of releasing substandard products.

Advanced Image Processing and Algorithm Development

Effective automated visual inspection goes beyond capturing high-resolution images; it requires sophisticated image processing and advanced algorithms. This is where artificial intelligence (AI) and machine learning (ML) technologies play a transformative role.

-

Image Enhancement and Noise Reduction: Image processing algorithms are essential for enhancing image quality and filtering out noise. Techniques like background subtraction, contrast enhancement, and edge detection improve the clarity of the images, making defect identification more accurate and reliable. This pre-processing step is vital for optimal performance of the automated inspection system.

-

AI-Powered Defect Classification: Machine learning, particularly deep learning models, excels in automated defect classification. These algorithms learn from vast datasets of images, identifying patterns and classifying various defect types with exceptional accuracy. This significantly reduces the reliance on manual review and minimizes human error.

-

Deep Learning for Complex Variations: The ability of deep learning models to handle variations in vial appearance and defect types is a significant advantage. Traditional methods struggle with these complexities, but deep learning algorithms adapt and learn, continually improving their accuracy and robustness over time. This adaptability is key to ensuring consistent performance across diverse manufacturing batches.

-

Algorithm Optimization for Accuracy: Continuous optimization of the algorithms is paramount for minimizing false positives and false negatives. This involves fine-tuning model parameters, improving feature extraction techniques, and regularly retraining the models with updated datasets. Optimized algorithms guarantee high accuracy and reliable results during automated visual inspection.

Integration of Spectroscopy and Other Analytical Techniques

Combining visual inspection with spectroscopic techniques provides a more comprehensive analysis of lyophilized vials, offering insights beyond what visual inspection alone can achieve.

-

Spectroscopic Data Enhancement: Spectroscopy, such as Raman spectroscopy or Near-Infrared (NIR) spectroscopy, provides information about the chemical composition and physical properties of the lyophilized material. This complements visual inspection by identifying defects that might not be visually apparent.

-

Combined Inspection for Robustness: Integrating spectroscopy with visual inspection creates a robust and comprehensive quality control system. The combined data from both techniques provides a holistic view of the product's integrity, leading to more reliable quality assessments.

-

Specific Spectroscopic Methods: Raman spectroscopy is useful for identifying specific chemical components and detecting potential degradation products. NIR spectroscopy is effective for measuring moisture content and other physical parameters within the lyophilized cake. These methods add layers of verification to the automated visual inspection process.

-

Multi-Technique Approach: Combining various analytical techniques, such as visual inspection, Raman spectroscopy, and NIR spectroscopy, creates a superior, multifaceted inspection system. This multi-technique approach minimizes the risk of overlooking critical defects and provides a high level of confidence in product quality.

Data Analytics and Reporting for Continuous Improvement

Data collected during automated visual inspection is invaluable for continuous improvement and process optimization.

-

Data Collection and Analysis: The automated system should efficiently collect and store data related to defect types, locations, frequencies, and associated process parameters. Analyzing this data reveals patterns and trends in defect occurrence.

-

Trend Identification and Process Optimization: Data analytics can pinpoint the root causes of defects, facilitating process improvements and minimizing future occurrences. This proactive approach enhances overall product quality and manufacturing efficiency.

-

Data-Driven Quality Control: Utilizing statistical process control (SPC) methodologies in conjunction with data analysis allows for the early detection of process deviations and the timely implementation of corrective actions. This data-driven approach leads to better control and reduces product variability.

-

Regulatory Compliance and Reporting: Comprehensive reporting is essential for demonstrating regulatory compliance and facilitating internal audits. Detailed reports on defect rates, process performance, and corrective actions are crucial for maintaining high quality standards.

Conclusion

Advanced techniques for automated visual inspection of lyophilized vials dramatically improve the efficiency and accuracy of pharmaceutical quality control. By combining high-resolution imaging, sophisticated image processing algorithms, spectroscopic methods, and robust data analytics, manufacturers can implement a comprehensive and highly reliable inspection system. This ensures high-quality, safe products reach patients. Investing in advanced automated visual inspection technology is crucial for maintaining high standards and ensuring the safety and efficacy of lyophilized products. Contact us today to learn more about optimizing your automated visual inspection of lyophilized vials and upgrading your pharmaceutical quality control procedures.

Featured Posts

-

Lily Collins Calvin Klein Photoshoot Image 5133601

May 12, 2025

Lily Collins Calvin Klein Photoshoot Image 5133601

May 12, 2025 -

Ncaa Softball History Made Karlyn Pickens Throws 78 2 Mph Fastball

May 12, 2025

Ncaa Softball History Made Karlyn Pickens Throws 78 2 Mph Fastball

May 12, 2025 -

Manon Fiorots Rise A Fighters Pursuit Of Gold

May 12, 2025

Manon Fiorots Rise A Fighters Pursuit Of Gold

May 12, 2025 -

Jamaica Observers Grand Slam Tournament Highlights

May 12, 2025

Jamaica Observers Grand Slam Tournament Highlights

May 12, 2025 -

Virginia Giuffres Terminal Illness Claim Following Prince Andrew Case

May 12, 2025

Virginia Giuffres Terminal Illness Claim Following Prince Andrew Case

May 12, 2025

Latest Posts

-

Will Sylvester Stallone Have A Larger Role In Future Jason Statham Films

May 12, 2025

Will Sylvester Stallone Have A Larger Role In Future Jason Statham Films

May 12, 2025 -

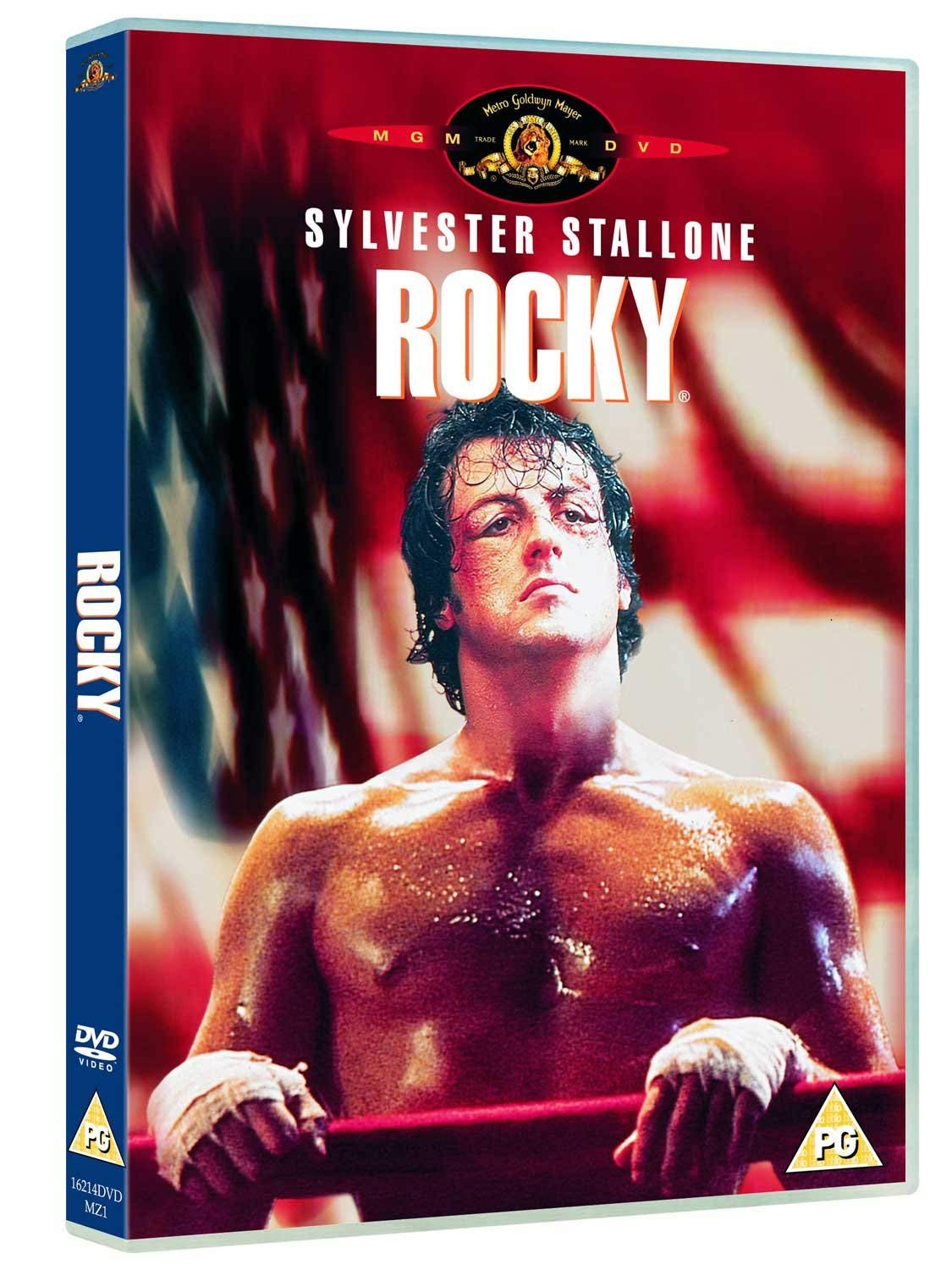

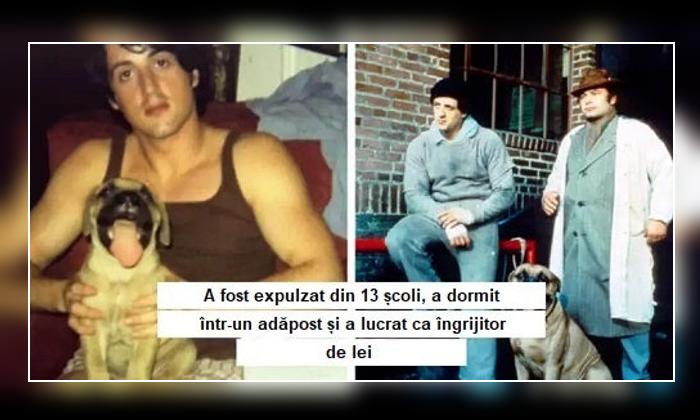

Plata Lui Sylvester Stallone Pentru Fiecare Film Rocky

May 12, 2025

Plata Lui Sylvester Stallone Pentru Fiecare Film Rocky

May 12, 2025 -

Stallone And Statham Is Stallones Appearance A Setup For A Bigger Role

May 12, 2025

Stallone And Statham Is Stallones Appearance A Setup For A Bigger Role

May 12, 2025 -

Cat A Incasat Sylvester Stallone Pentru Filmele Rocky

May 12, 2025

Cat A Incasat Sylvester Stallone Pentru Filmele Rocky

May 12, 2025 -

Sylvester Stallone Si Rocky O Analiza Financiara

May 12, 2025

Sylvester Stallone Si Rocky O Analiza Financiara

May 12, 2025