Automated Visual Inspection Of Lyophilized Vials: A Practical Guide To Troubleshooting

Table of Contents

Common Issues in Automated Visual Inspection of Lyophilized Vials

Automated visual inspection systems, while highly effective, can encounter several challenges impacting their accuracy and efficiency. Understanding these common problems is the first step towards effective troubleshooting.

Image Acquisition Problems

High-quality images are fundamental to accurate defect detection. Poor image acquisition can lead to missed defects or false positives. Several factors contribute to this:

- Poor lighting: Inconsistent illumination creates shadows and highlights, obscuring subtle defects. Variations in lighting intensity across the vial can lead to misinterpretations by the inspection system.

- Focus issues: Blurred images make it impossible to accurately assess the vial's contents and identify defects. This can result from incorrect focusing distance or vibrations affecting the system's stability.

- Incorrect camera settings: Incorrect exposure, gain, or white balance settings can lead to distorted, under-exposed, or over-exposed images, compromising the accuracy of the automated visual inspection. Low-resolution cameras may not capture the fine details needed for thorough analysis.

Bullet Points:

- Calibrate your lighting system regularly using standardized light sources and ensure uniform illumination across the field of view.

- Use high-resolution cameras with appropriate lenses (macro lenses are often preferred) to capture sharp, detailed images of the lyophilized cake and vial.

- Optimize camera settings (exposure, gain, white balance) for optimal image quality. This often requires experimentation and fine-tuning to achieve the best contrast and clarity.

- Implement a robust image acquisition quality control (QA/QC) process, regularly checking image quality and making adjustments as needed. Employ visual inspection checks in conjunction with automated systems for quality assurance.

Defect Detection Challenges

Even with high-quality images, accurate defect detection can be challenging. Lyophilized vials often exhibit natural variations in cake appearance, making it difficult to distinguish between acceptable variations and genuine defects.

- Distinguishing acceptable variations from defects: Slight variations in cake appearance, such as minor cracks or inconsistencies in the sublimation process, can be difficult for algorithms to differentiate from significant defects. This can lead to either missed defects or an excessive number of false positives.

- False positives: Reflections from the vial's surface, shadows cast by the cake, or dust particles can be misinterpreted as defects, leading to unnecessary rejection of good vials.

- Missed defects: Limitations in the image processing algorithms or insufficient training data can result in missed defects, compromising product quality.

Bullet Points:

- Fine-tune your defect detection algorithms using a large and representative sample of vials, including both good and defective examples, to improve accuracy and reduce false positives.

- Implement advanced image processing techniques (e.g., noise reduction, contrast enhancement, edge detection) to improve the clarity and definition of the images, facilitating better defect identification.

- Regularly review and update your defect library with new images and classifications to reflect changes in product characteristics or manufacturing processes.

- Consider using multiple inspection methods (e.g., combining automated visual inspection with other analytical techniques like weight checks or headspace analysis) for enhanced accuracy and reduced error rates.

Maintaining System Integrity

Consistent performance of automated visual inspection systems relies heavily on proper maintenance and calibration. Neglecting this can lead to inaccurate results and system downtime.

- Regular cleaning and calibration: Accumulation of dust, debris, or fingerprints on optical components can significantly impact image quality. Regular calibration ensures the system maintains its accuracy and precision.

- Proper vial handling and presentation: Incorrectly oriented or damaged vials can lead to inaccurate inspections and potential system damage. A robust vial handling system is crucial.

- Preventative maintenance: A preventative maintenance program extends the life of the equipment, minimizes downtime, and ensures consistent performance.

Bullet Points:

- Develop a comprehensive preventive maintenance schedule, including regular cleaning, calibration, and component replacement as needed. Document all maintenance activities thoroughly.

- Train personnel on proper system operation and cleaning procedures to ensure consistent performance and prevent accidental damage.

- Regularly validate the system's accuracy and precision using certified reference materials to confirm it meets predefined performance standards.

- Use high-quality consumables and replacement parts from reputable suppliers to ensure optimal system performance and longevity.

Troubleshooting Strategies for Automated Visual Inspection Systems

A systematic approach to troubleshooting is vital for resolving issues effectively and efficiently.

Systematic Approach to Problem Solving

Troubleshooting should follow a structured methodology:

- Identify the specific problem: Is it low image quality, a high false positive rate, or missed defects? Pinpointing the exact nature of the problem is the first step towards a solution.

- Isolate the cause: Is the issue due to poor lighting, incorrect algorithm settings, a malfunctioning component, or a problem with vial handling? Systematic investigation is crucial.

- Implement corrective actions and retest: Once the cause has been identified, implement appropriate corrective actions and retest the system to verify the problem has been resolved.

Bullet Points:

- Keep detailed logs of all inspections and troubleshooting efforts. This creates a valuable record for future reference and helps to identify recurring problems.

- Use a structured problem-solving methodology (e.g., a fault tree analysis or 5 Whys analysis) to systematically investigate the root cause of issues.

- Consult the system's documentation and manufacturer's support. The documentation often provides valuable troubleshooting tips and guidelines.

Leveraging Data Analytics for Improvement

Data analytics plays a crucial role in optimizing automated visual inspection systems.

- Analyzing inspection data: Reviewing inspection data can reveal recurring issues and trends, identifying areas where improvements are needed.

- Data-driven optimization: Analyzing data can identify optimal inspection parameters, leading to more accurate and efficient inspections.

- Algorithm improvement: Historical data can be used to train and improve the defect detection algorithms, leading to better performance over time.

Bullet Points:

- Implement a data management system to track inspection results, including images, defect classifications, and system performance metrics.

- Use statistical process control (SPC) techniques to monitor the system's performance and identify deviations from expected values.

- Explore advanced analytics techniques like machine learning to develop more robust and accurate defect detection algorithms.

Conclusion

Successful automated visual inspection of lyophilized vials requires a proactive approach to troubleshooting. By understanding common issues, implementing robust troubleshooting strategies, and leveraging data analytics, pharmaceutical manufacturers can significantly improve the accuracy, efficiency, and reliability of their inspection processes. Regular maintenance, continuous improvement of algorithms, and a commitment to quality control are essential for ensuring the consistent delivery of high-quality lyophilized products. Don't let inspection challenges compromise your product quality – invest in comprehensive troubleshooting techniques for your automated visual inspection of lyophilized vials. Properly implemented, automated visual inspection of lyophilized vials offers significant improvements in speed, accuracy, and consistency, contributing to higher overall product quality.

Featured Posts

-

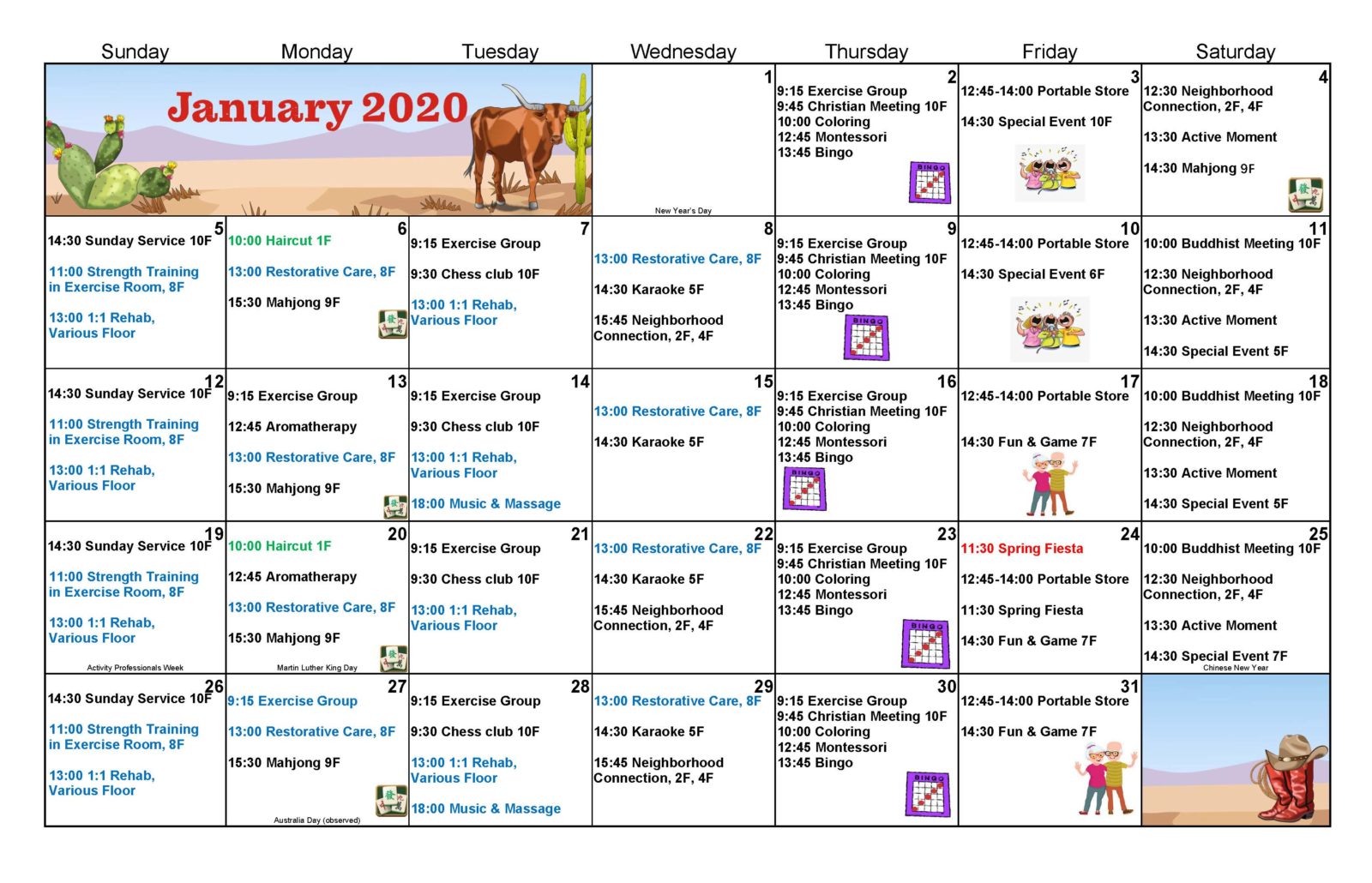

2024 Senior Calendar Trips Activities And Events

May 11, 2025

2024 Senior Calendar Trips Activities And Events

May 11, 2025 -

Combat Ufc 315 Montreal Zahabi Contre Aldo Attentes Et Enjeux

May 11, 2025

Combat Ufc 315 Montreal Zahabi Contre Aldo Attentes Et Enjeux

May 11, 2025 -

Shane Lowrys Supportive Message To Rory Mc Ilroy After The Masters A Testament To Their Friendship

May 11, 2025

Shane Lowrys Supportive Message To Rory Mc Ilroy After The Masters A Testament To Their Friendship

May 11, 2025 -

Can Adam Sandler Bridge The Divide In Modern America A Look At His Potential Influence

May 11, 2025

Can Adam Sandler Bridge The Divide In Modern America A Look At His Potential Influence

May 11, 2025 -

The Unpaid 1 Tom Cruises Ongoing Debt To Tom Hanks

May 11, 2025

The Unpaid 1 Tom Cruises Ongoing Debt To Tom Hanks

May 11, 2025