Figure AI's Humanoid Robots: A Potential UPS Partnership

Table of Contents

Figure AI's Humanoid Robot Capabilities: A Perfect Fit for UPS?

H2: Advanced Dexterity and Manipulation: Figure AI's humanoid robots boast unparalleled dexterity and manipulation capabilities, far surpassing traditional automated systems. Their advanced design allows them to handle a wide variety of packages with precision and speed.

- Picking: Robots can accurately pick up items of different shapes, sizes, and weights.

- Placing: Precise placement ensures items are properly sorted and stored.

- Sorting: Robots can efficiently sort packages based on destination, size, or other criteria.

- Stacking: They can stack packages securely and efficiently, maximizing warehouse space.

This superior dexterity translates to significant advantages over traditional automated systems, which often struggle with the variability of real-world package handling. Keywords: dexterity, manipulation, package handling, sorting, automation, efficiency.

H2: Navigation and Mobility in Complex Environments: Unlike many automated systems limited to structured environments, Figure AI's robots navigate complex warehouse layouts with ease. Their advanced navigation systems include:

- Obstacle Avoidance: Sophisticated sensors allow robots to detect and avoid obstacles, ensuring safe and efficient movement.

- Path Planning: Intelligent algorithms optimize routes, minimizing travel time and maximizing efficiency.

- Adaptability: The robots can adapt to changing warehouse conditions, such as rearranged shelving or unexpected obstacles.

This adaptability is crucial in the dynamic environments of modern logistics, where flexibility is key. Keywords: navigation, mobility, warehouse automation, obstacle avoidance, path planning, adaptability.

H2: AI-Powered Intelligence and Learning: The robots' intelligence is powered by advanced artificial intelligence and machine learning. This means:

- Continuous Improvement: The robots learn from their experiences, constantly refining their performance and adapting to new tasks.

- Task Optimization: AI algorithms optimize workflows, ensuring maximum efficiency and minimizing errors.

- System Integration: The potential for seamless integration with UPS's existing systems offers a significant advantage, facilitating data analysis and real-time tracking.

This AI-powered intelligence is a game-changer, enabling the robots to handle increasingly complex tasks and learn from vast amounts of data. Keywords: artificial intelligence, machine learning, AI-powered, task optimization, system integration, data analysis.

H3: Safety and Reliability in a Warehouse Setting: Safety is paramount. Figure AI's robots are designed with numerous safety features, including:

- Emergency Stop Mechanisms: Instantaneous shutdown capabilities ensure immediate safety in unforeseen situations.

- Collision Avoidance Systems: Advanced sensors prevent collisions with humans and other objects.

- Robust Construction: Durable construction ensures reliable operation even in demanding warehouse environments.

The robots' reliability significantly reduces the risk of human error, improving overall warehouse safety. Keywords: safety, reliability, warehouse safety, risk reduction, human error.

Potential Benefits of a Figure AI-UPS Partnership

H2: Increased Efficiency and Productivity: The integration of Figure AI's robots could dramatically boost UPS's efficiency and productivity. This could translate to:

- Increased Throughput: Faster package handling and sorting could significantly increase warehouse throughput.

- Cost Savings: Automation reduces labor costs and improves operational efficiency.

- Improved Order Fulfillment: Faster processing and delivery lead to increased customer satisfaction.

These improvements could offer a significant competitive advantage in the fast-paced logistics industry. Keywords: efficiency, productivity, throughput, cost savings, order fulfillment, customer satisfaction.

H2: Enhanced Scalability and Flexibility: Figure AI's robots offer unparalleled scalability and flexibility:

- Adapting to Demand: Robots can easily handle fluctuating demands, particularly during peak seasons.

- Easy Scaling: Deploying additional robots is relatively straightforward, allowing UPS to scale operations up or down as needed.

- Flexible Deployment: Robots can be deployed to different warehouse locations, maximizing resource utilization.

This scalability is essential for a company like UPS, which needs to adapt to constantly changing logistical demands. Keywords: scalability, flexibility, peak season, demand fluctuations, deployment, adaptability.

H2: Addressing Labor Shortages in the Logistics Industry: The logistics industry faces significant labor shortages. Humanoid robots can help alleviate these challenges by:

- Filling Labor Gaps: Robots can perform repetitive and physically demanding tasks, freeing up human workers for more complex roles.

- Improved Workforce Efficiency: Augmenting the human workforce with robots improves overall efficiency.

- Human-Robot Collaboration: A collaborative approach allows humans and robots to work together, maximizing the strengths of both.

This collaboration can lead to a more efficient and productive workforce. Keywords: labor shortages, workforce efficiency, human-robot collaboration, logistics workforce.

Challenges and Considerations

H2: Integration with Existing Infrastructure: Integrating humanoid robots into UPS's existing infrastructure will present challenges:

- System Integration: Seamless integration with existing warehouse management systems (WMS) is critical.

- Infrastructure Upgrades: Upgrades or modifications to existing facilities may be necessary.

- Compatibility Issues: Ensuring compatibility between different systems and software requires careful planning.

Addressing these integration challenges is crucial for a successful implementation. Keywords: system integration, infrastructure upgrade, compatibility, workflow integration.

H2: Cost of Implementation and Return on Investment: The initial investment in humanoid robots is significant. However:

- Long-Term ROI: The long-term return on investment (ROI) is potentially substantial, due to cost savings and increased efficiency.

- Cost-Effectiveness: Compared to other automation solutions, humanoid robots may offer a more cost-effective solution in the long run.

- Reduced Labor Costs: The robots' potential to reduce reliance on human labor can significantly decrease operational expenses over time.

A thorough cost-benefit analysis is essential to assess the viability of such an investment. Keywords: cost of implementation, return on investment, cost-effectiveness, ROI, automation costs.

H2: Ethical and Societal Implications: The widespread adoption of humanoid robots raises ethical concerns:

- Job Displacement: Concerns about job displacement require careful consideration and proactive measures, such as retraining programs.

- Responsible AI: The ethical development and deployment of AI in logistics are paramount.

- New Job Creation: While some jobs may be displaced, the adoption of robotics may create new job opportunities in areas such as robot maintenance and programming.

Addressing these ethical concerns is crucial to ensure responsible technological advancement. Keywords: ethical implications, job displacement, responsible AI, retraining programs, AI ethics.

Conclusion: The Future of Logistics with Figure AI Humanoid Robots and UPS

A partnership between Figure AI and UPS has the potential to revolutionize the logistics industry. While challenges exist regarding integration and ethical considerations, the potential benefits – increased efficiency, scalability, and solutions to labor shortages – are substantial. Figure AI's humanoid robots, with their advanced dexterity, AI-powered intelligence, and adaptability, could reshape warehouse operations and redefine the future of delivery. To learn more about Figure AI humanoid robots and their potential impact on the future of logistics with UPS, visit the Figure AI website or contact UPS directly for information about their automation initiatives. Keywords: Figure AI humanoid robots, UPS partnership, future of logistics, warehouse automation, supply chain optimization.

Featured Posts

-

Trump Weighs In On Us Canada Ties Ahead Of Canadian Election

Apr 30, 2025

Trump Weighs In On Us Canada Ties Ahead Of Canadian Election

Apr 30, 2025 -

Cardinale Becciu Il Papa Respinge Le Speculazioni Sulle Dimissioni

Apr 30, 2025

Cardinale Becciu Il Papa Respinge Le Speculazioni Sulle Dimissioni

Apr 30, 2025 -

Rapport Kering Amf Cp 2025 E1021784 Publication Du 24 Fevrier 2025

Apr 30, 2025

Rapport Kering Amf Cp 2025 E1021784 Publication Du 24 Fevrier 2025

Apr 30, 2025 -

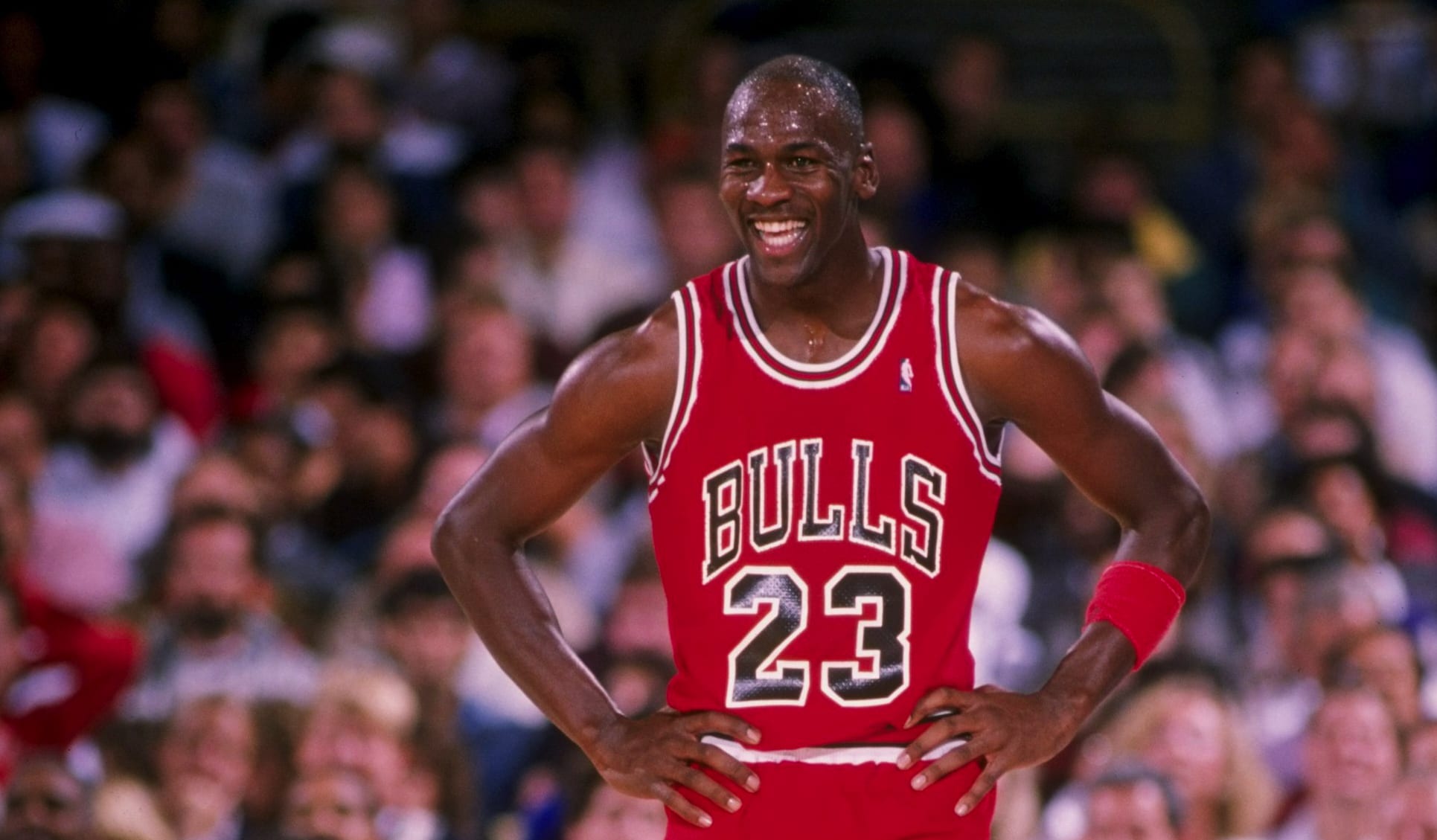

Essential Michael Jordan Facts A Quick Overview

Apr 30, 2025

Essential Michael Jordan Facts A Quick Overview

Apr 30, 2025 -

Apples E162 Million Privacy Fine A Breakdown Of The Allegations And Penalties

Apr 30, 2025

Apples E162 Million Privacy Fine A Breakdown Of The Allegations And Penalties

Apr 30, 2025