Ford's EV Strategy: Sharing Battery Plant Production With Nissan

Table of Contents

The BlueOval SK Battery Plant Joint Venture

A cornerstone of Ford's EV strategy is its joint venture with SK On, a South Korean battery manufacturer. This partnership, initially focused solely on Ford's needs, has now expanded to include Nissan, creating a powerful three-way collaboration. This joint venture, often referred to as the BlueOval SK battery plant, aims to significantly increase battery cell and pack production for both Ford and Nissan's electric vehicle lineups.

The plants are strategically located in multiple sites across the United States, ensuring geographic diversification and reducing reliance on single-source production. The exact production capacity varies by location, but the combined output is substantial, representing a massive investment in domestic battery manufacturing for both automakers.

- Battery Technologies: The plants produce a range of battery technologies, including Lithium Iron Phosphate (LFP) batteries known for their cost-effectiveness and Nickel Cobalt Manganese (NCM) batteries offering higher energy density. This diversification allows both Ford and Nissan to offer EVs catering to various price points and performance requirements.

- Production Volume: The projected annual production volume of battery cells and packs is in the hundreds of gigawatt-hours (GWh), signifying a significant contribution to the overall North American EV battery supply chain. This scale is crucial for meeting the growing demand for electric vehicles.

- Ford's Investment: Ford has committed billions of dollars to this joint venture, highlighting its commitment to securing a reliable and cost-effective battery supply for its burgeoning electric vehicle portfolio. This massive investment underscores the critical role battery production plays in Ford's overall EV strategy.

Benefits for Ford's EV Production

The partnership with Nissan and SK On offers several significant advantages for Ford's EV production strategy:

- Cost Reduction: Shared production significantly reduces the per-unit cost of battery cells and packs through economies of scale. This cost advantage is crucial for making electric vehicles more affordable and competitive with gasoline-powered vehicles.

- Increased Capacity: The combined production capacity of the BlueOval SK plants, amplified by the Nissan collaboration, ensures Ford has sufficient battery supply to meet its ambitious EV production targets. This avoids potential bottlenecks and delays in EV rollout.

- Reduced Risk: Diversifying battery sourcing by collaborating with Nissan and SK On reduces Ford's reliance on a single supplier, mitigating risks associated with supply chain disruptions, material shortages, or manufacturing challenges.

This partnership directly accelerates Ford's EV rollout plans by guaranteeing a secure and affordable supply of high-quality batteries, enabling the company to bring more electric vehicles to market faster.

Nissan's Strategic Alignment and Benefits

The partnership with Ford and SK On is equally advantageous for Nissan, contributing significantly to their own electric vehicle goals.

- Access to Advanced Technology: Nissan gains access to cutting-edge battery technology and manufacturing expertise from both Ford and SK On, accelerating their own EV development and innovation.

- Shared Investment: Sharing the substantial investment costs of battery production reduces the financial risk for Nissan, freeing up resources for other aspects of their EV strategy.

- Future Collaborations: This joint venture could pave the way for future collaborations between Ford and Nissan, potentially extending beyond battery production to other areas of vehicle development and manufacturing. This synergistic relationship could lead to further innovation and efficiency gains for both companies.

Challenges and Risks of the Partnership

While the Ford-Nissan-SK On partnership offers numerous benefits, potential challenges and risks must be addressed:

-

Differing Corporate Cultures: Integrating the operational processes and decision-making within a three-party joint venture requires effective communication and coordination to overcome potential conflicts arising from differing corporate cultures.

-

Supply Chain Disruptions: The global supply chain remains vulnerable to unforeseen disruptions. Maintaining a resilient supply chain for battery materials and components is crucial for the success of the partnership.

-

Conflicts of Interest: Balancing the needs and priorities of three major automotive players within a single joint venture requires careful management to avoid potential conflicts of interest.

-

Over-Reliance on a Single Supplier (SK On): While diversification is achieved through partnership with Nissan, a significant reliance on SK On for the cells still presents a risk.

-

Potential Production Delays: Unforeseen circumstances, such as natural disasters or geopolitical events, could potentially cause production delays, impacting both Ford and Nissan's EV production schedules.

-

Complexities of Multi-Party Joint Venture: Managing the complexities of a multi-party joint venture requires robust governance structures and effective communication to ensure smooth operations and efficient decision-making.

-

Maintaining Competitive Advantage: The EV market is highly competitive, and maintaining a competitive advantage requires constant innovation and adaptation. The partnership must continuously adapt to the rapidly evolving landscape.

Conclusion

Ford's partnership with Nissan on battery production, facilitated through the BlueOval SK joint venture, represents a significant step in its ambitious EV strategy. This collaboration offers considerable benefits, including reduced costs, increased capacity, and accelerated EV rollout. However, the partnership also presents challenges that need careful management. Successfully navigating these challenges will be crucial for both Ford and Nissan to fully realize the potential of this strategic alliance and maintain a competitive edge in the rapidly expanding electric vehicle market.

Call to Action: Stay informed on the developments of Ford's EV strategy and its impact on the future of electric vehicles. Follow our updates for the latest news and insights on Ford's EV advancements and its strategic alliances, such as the vital battery production partnership with Nissan. Learn more about Ford's commitment to electric vehicle innovation and the future of sustainable transportation.

Featured Posts

-

L Espace Julien Un Apercu Avant Le Hellfest Pour Les Romanciers

May 22, 2025

L Espace Julien Un Apercu Avant Le Hellfest Pour Les Romanciers

May 22, 2025 -

Are You Still There Bbc Breakfast Presenter Deals With Unexpected Guest Interruption

May 22, 2025

Are You Still There Bbc Breakfast Presenter Deals With Unexpected Guest Interruption

May 22, 2025 -

Ai Startup Cohere Sales Doubled This Year

May 22, 2025

Ai Startup Cohere Sales Doubled This Year

May 22, 2025 -

Exploring The Sound Perimeter The Science Of Musical Connection

May 22, 2025

Exploring The Sound Perimeter The Science Of Musical Connection

May 22, 2025 -

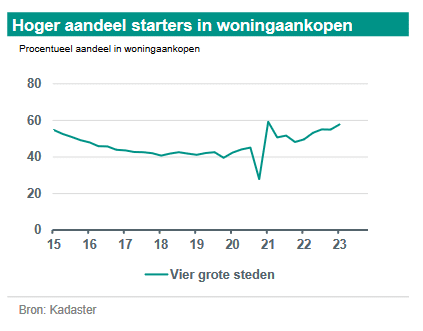

Abn Amro Hogere Huizenprijzen Ondanks Renteverhogingen

May 22, 2025

Abn Amro Hogere Huizenprijzen Ondanks Renteverhogingen

May 22, 2025

Latest Posts

-

Toledo Gas Prices Recent Trends And Predictions

May 22, 2025

Toledo Gas Prices Recent Trends And Predictions

May 22, 2025 -

Significant Gas Price Hike Up Almost 20 Cents Per Gallon

May 22, 2025

Significant Gas Price Hike Up Almost 20 Cents Per Gallon

May 22, 2025 -

Columbus Gas Prices 2 83 To 3 31 Per Gallon

May 22, 2025

Columbus Gas Prices 2 83 To 3 31 Per Gallon

May 22, 2025 -

Decreased Gas Prices In Toledo What Drivers Need To Know

May 22, 2025

Decreased Gas Prices In Toledo What Drivers Need To Know

May 22, 2025 -

20 Cent Gas Price Hike Impact On Consumers And The Economy

May 22, 2025

20 Cent Gas Price Hike Impact On Consumers And The Economy

May 22, 2025