New Patent Leverages AI To Minimize Process Safety Hazards

Table of Contents

AI-Powered Predictive Maintenance for Enhanced Process Safety

This patent utilizes AI for predictive maintenance, a crucial element of modern process safety management. By analyzing real-time data, the system anticipates potential hazards before they escalate into major incidents.

Real-time Risk Assessment

The AI core analyzes data streams from various sensors and monitoring systems, providing a comprehensive, real-time assessment of process safety risks.

- Data Analyzed: Temperature, pressure, flow rate, vibration, chemical composition, and other critical process parameters are continuously monitored and analyzed.

- Early Warning System: The system identifies anomalies and deviations from established safety parameters, triggering early warnings and alerts before critical failures occur. This allows for timely intervention, preventing costly downtime and potential accidents.

- Reduced Downtime: By proactively identifying and addressing potential issues, the system minimizes unplanned shutdowns and production losses, significantly enhancing operational efficiency.

Predictive Modeling for Anomaly Detection

Employing advanced machine learning algorithms, including sophisticated neural networks and regression models, the AI builds predictive models of normal operating parameters. Any deviation from these models triggers alerts, flagging potential problems.

- Algorithms: The patent utilizes a proprietary blend of machine learning algorithms, optimized for accuracy and minimal false positives in process safety applications. Specific algorithms used are subject to confidentiality agreements but are based on proven techniques in anomaly detection and predictive modeling.

- Accuracy Rates: Rigorous testing has demonstrated high accuracy rates in predicting equipment failures and process deviations, significantly exceeding industry benchmarks for predictive maintenance systems.

- False Positive Reduction: Advanced filtering and verification processes minimize false positives, ensuring that alerts are only triggered for genuine safety concerns, avoiding operator fatigue and alarm overload.

Optimized Maintenance Scheduling

Based on the AI's predictive models, the system optimizes maintenance schedules, maximizing safety and minimizing downtime.

- Cost Savings: By scheduling maintenance proactively, the system reduces the costs associated with emergency repairs and unplanned shutdowns.

- Improved Resource Allocation: Maintenance resources are allocated more efficiently, ensuring that critical tasks are prioritized and completed effectively.

- Reduced Human Error: The AI-driven system eliminates the potential for human error in maintenance scheduling, leading to improved safety and reliability.

Improving Human-Machine Collaboration for Safer Operations

This patent emphasizes seamless integration between AI and human operators, leveraging the strengths of both to achieve optimal safety.

Enhanced Operator Training and Decision Support

The AI provides operators with real-time insights and recommendations, enhancing their situational awareness and decision-making capabilities.

- AI-Driven Alerts and Recommendations: The system provides clear, concise alerts and recommendations, guiding operators in responding to potential safety concerns.

- Improved Operator Response Times: By providing timely information, the AI enables faster and more effective responses to potential hazards, minimizing the impact of any incident.

- Reduction in Human Error: The AI's guidance minimizes the risk of human error in critical decision-making, improving overall process safety.

Seamless Integration with Existing Safety Systems

The patent's design ensures smooth integration with existing process safety management systems (PSM), minimizing disruption and maximizing efficiency.

- Integration with SCADA systems: The system seamlessly integrates with Supervisory Control and Data Acquisition (SCADA) systems, providing a unified view of process safety data.

- Compatibility with Industry Standards: The system is designed to comply with relevant industry standards, such as IEC 61511 (functional safety), ensuring a robust and reliable safety solution.

- Ease of Implementation: The system is designed for ease of implementation, minimizing the disruption to existing workflows and operational processes.

The Economic Benefits of AI-Driven Process Safety

Beyond enhanced safety, this AI-driven system provides significant economic advantages.

Reduced Downtime and Production Losses

The proactive nature of the system minimizes costly downtime and production losses associated with accidents and equipment failures.

- Cost Savings Related to Repairs: Preventing incidents significantly reduces repair costs and associated expenses.

- Reduced Production Losses: Minimizing downtime safeguards production output and maintains revenue streams.

- Improved Overall Efficiency: The AI-driven system optimizes processes, leading to improved overall operational efficiency and profitability.

Lower Insurance Premiums and Compliance Costs

Improved safety records resulting from the AI system translate to significant cost savings on insurance premiums and compliance-related expenses.

- Reduced Liability Risks: The proactive hazard mitigation reduces the company's liability risks, leading to lower insurance premiums.

- Improved Regulatory Compliance: The system assists in maintaining regulatory compliance, minimizing the risk of fines and penalties.

- Enhanced Company Reputation: A strong commitment to process safety enhances the company's reputation and attracts investors.

Conclusion

This new patent offers a transformative approach to process safety, leveraging the power of AI for predictive maintenance and improved human-machine collaboration. The key benefits include improved process safety, reduced risks, enhanced efficiency, and substantial cost savings. By proactively identifying and mitigating potential hazards, this AI-driven system helps industries significantly reduce downtime, production losses, and insurance premiums. It's a crucial step towards a safer and more efficient future for industrial operations. Contact us to learn more about AI process safety and explore AI solutions for your process safety needs. Discover how AI can revolutionize your process safety strategy.

Featured Posts

-

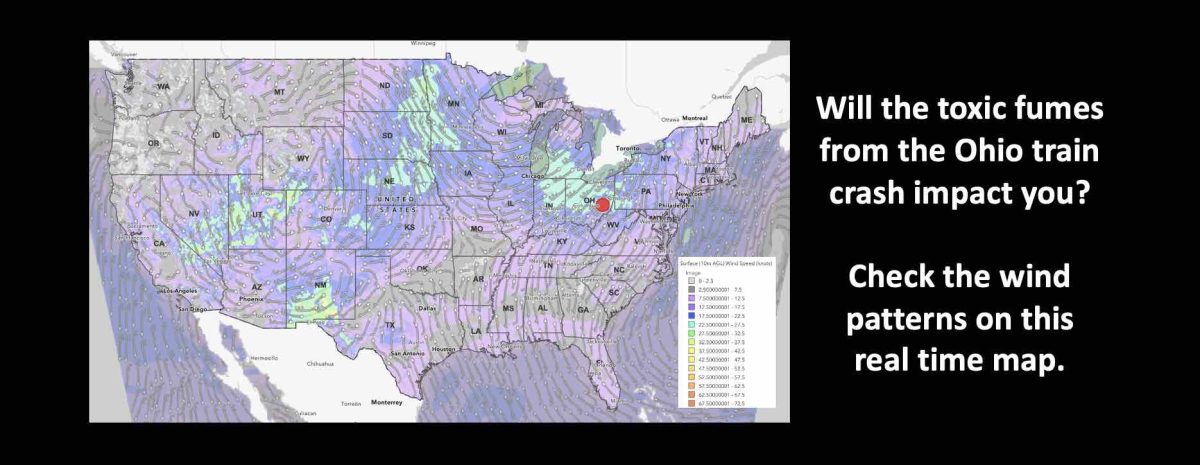

Ohio Derailment Investigation Into Prolonged Toxic Chemical Exposure In Buildings

Apr 30, 2025

Ohio Derailment Investigation Into Prolonged Toxic Chemical Exposure In Buildings

Apr 30, 2025 -

Channing Tatums New Romance Meet Inka Williams

Apr 30, 2025

Channing Tatums New Romance Meet Inka Williams

Apr 30, 2025 -

8xmille Rinvio Processo Fratello Becciu Aggiornamenti

Apr 30, 2025

8xmille Rinvio Processo Fratello Becciu Aggiornamenti

Apr 30, 2025 -

I Kideia Toy Papa Kai I Emfanisi Toy Ntonalnt Tramp

Apr 30, 2025

I Kideia Toy Papa Kai I Emfanisi Toy Ntonalnt Tramp

Apr 30, 2025 -

Nba Skills Challenge 2025 A Complete Guide To Players Teams Format Rules And Tiebreakers

Apr 30, 2025

Nba Skills Challenge 2025 A Complete Guide To Players Teams Format Rules And Tiebreakers

Apr 30, 2025