Reducing Process Safety Hazards: A Novel AI-Based Patent Solution

Table of Contents

Understanding the Scope of Process Safety Hazards

Process safety hazards encompass any potential event or condition within a process that could lead to undesirable consequences, including significant economic losses, environmental damage, and human casualties. The severity of these incidents can range from minor operational disruptions to catastrophic events with devastating impacts.

Industries Affected

Numerous industries are vulnerable to process safety incidents, including:

- Chemical Industry: Explosions, fires, toxic gas releases, and spills of hazardous materials.

- Oil & Gas Industry: Blowouts, pipeline ruptures, fires, and explosions.

- Manufacturing Industry: Equipment failures, fires, explosions, and releases of hazardous substances.

- Pharmaceutical Industry: Explosions, fires, and the release of toxic or flammable materials.

- Food Processing Industry: Fires, explosions, and contamination of products.

These industries are subject to stringent safety regulations and standards, such as those set by OSHA (Occupational Safety and Health Administration) in the US and ISO (International Organization for Standardization) globally. Failure to comply can lead to severe penalties and reputational damage.

Traditional Approaches to Hazard Mitigation

Traditional methods of process safety hazard mitigation often rely on reactive measures and have limitations. These include:

- Safety Audits: While crucial, audits are often infrequent and may not identify all potential hazards.

- Training Programs: Effective training is essential, but human error remains a significant contributor to incidents.

- Emergency Response Plans: These are crucial for response, but prevention is paramount.

- Safety Management Systems (SMS): While effective, SMS are often complex and require significant resources to implement and maintain.

These methods often struggle with real-time monitoring and proactive hazard identification. They typically react to events rather than prevent them.

The AI-Based Patent Solution: Core Functionality

Our AI-based patent solution offers a paradigm shift in process safety management by providing real-time monitoring, predictive modeling, and proactive anomaly detection. This system leverages advanced artificial intelligence algorithms to analyze data from various sources and identify potential hazards before they escalate.

Data Acquisition and Integration

The system integrates data from diverse sources, including:

- Sensors: Temperature, pressure, flow rate, vibration, and gas detectors.

- Control Systems: Process parameters, equipment status, and operational data.

- Historical Records: Maintenance logs, incident reports, and safety audits.

This comprehensive data integration allows for a holistic understanding of the process and its potential vulnerabilities.

Predictive Modeling and Anomaly Detection

The core of the system uses sophisticated machine learning and deep learning algorithms to:

- Develop predictive models: These models anticipate potential hazards based on historical data and real-time process parameters.

- Detect anomalies: The AI identifies deviations from normal operating conditions, flagging potential issues before they lead to incidents. These anomalies can include:

- Equipment malfunctions

- Process deviations

- Operator errors

- Environmental changes

Alerting and Response Mechanisms

The system provides timely alerts and triggers appropriate responses through:

- Visual warnings: Displays on operator interfaces highlighting potential hazards.

- Audible alarms: Immediate alerts to draw attention to critical situations.

- Automated shutdowns: Automatic cessation of operations to prevent escalation of hazardous events.

- Automated reports: Detailed reports of detected anomalies for further investigation and analysis.

Benefits of the AI-Based Solution for Reducing Process Safety Hazards

This AI-based solution offers significant advantages over traditional methods in reducing process safety hazards:

Enhanced Safety Performance

The system's proactive approach to hazard identification and timely intervention leads to:

- Significant reduction in process safety incidents.

- Improved safety compliance.

- Creation of a safer working environment.

Cost Savings

Implementing the AI solution can lead to substantial cost savings by:

- Reducing maintenance costs: Proactive identification of equipment issues minimizes downtime and repair expenses.

- Avoiding production losses: Preventing incidents safeguards production efficiency and minimizes lost output.

- Lower insurance premiums: Improved safety performance can result in reduced insurance costs.

Improved Operational Efficiency

The system streamlines operations and enhances productivity through:

- Optimized process control: The AI-driven system fine-tunes processes for optimal performance and efficiency.

- Reduced human error: Automation minimizes the risk of human error in critical operations.

- Faster response times: Immediate alerts and automated responses ensure rapid intervention in hazardous situations.

Conclusion

This novel AI-based patent solution offers a significant advancement in reducing process safety hazards. By leveraging the power of artificial intelligence, this technology provides proactive hazard identification, predictive modeling, and real-time alerts, leading to enhanced safety performance, substantial cost savings, and improved operational efficiency. Companies seeking to improve their process safety management and minimize risks should explore the potential of this innovative solution. Learn more about how to implement this cutting-edge technology to significantly improve your process safety management and reduce hazards within your operations. Contact us today to discuss your specific needs and explore how this AI-powered solution can benefit your organization.

Featured Posts

-

Adidas Spring Sale Get Your 14 Slides Before They Re Gone

Apr 30, 2025

Adidas Spring Sale Get Your 14 Slides Before They Re Gone

Apr 30, 2025 -

Hkm Qdayy Dd Ryys Shbab Bn Jryr

Apr 30, 2025

Hkm Qdayy Dd Ryys Shbab Bn Jryr

Apr 30, 2025 -

Where To Watch Untucked Ru Pauls Drag Race Season 17 Episode 8 For Free

Apr 30, 2025

Where To Watch Untucked Ru Pauls Drag Race Season 17 Episode 8 For Free

Apr 30, 2025 -

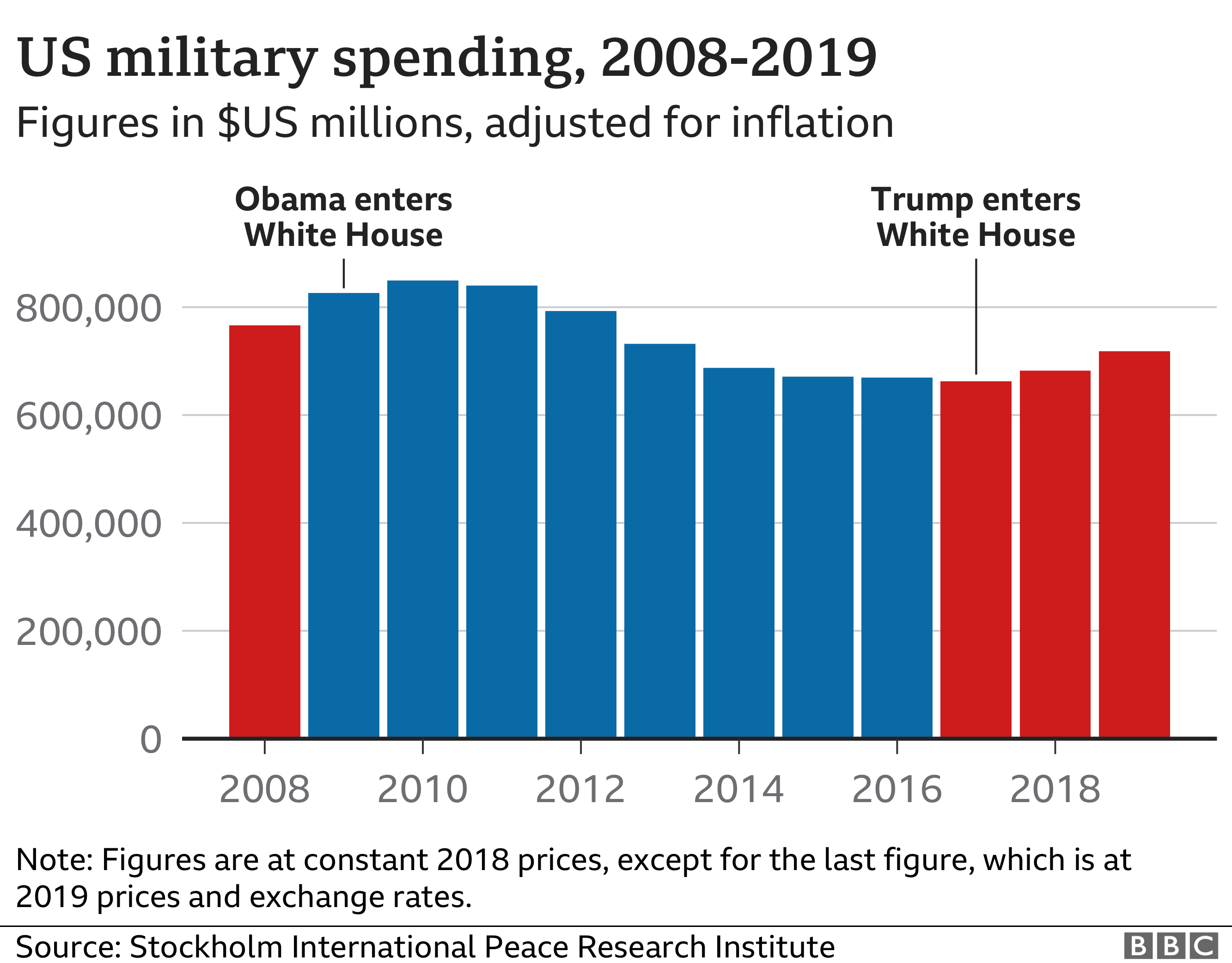

Military Spending Increase Analyzing Europes Response To Russia

Apr 30, 2025

Military Spending Increase Analyzing Europes Response To Russia

Apr 30, 2025 -

Yates And Dr Jessica Johnson A Powerful Black History Narrative

Apr 30, 2025

Yates And Dr Jessica Johnson A Powerful Black History Narrative

Apr 30, 2025