The Complexities Of Robotic Nike Sneaker Manufacturing

Table of Contents

The Technological Hurdles of Robotic Sneaker Production

Implementing robotic systems in sneaker factories presents numerous technological challenges. The intricate nature of sneaker assembly demands a level of precision and dexterity that current robotic systems often struggle to achieve.

Precision and Dexterity Challenges

Robots face significant hurdles in replicating the nuanced movements required for sneaker assembly. Many tasks involve delicate materials and complex stitching patterns.

- Variability in Material Properties: The diverse range of materials used in sneaker construction—leather, synthetic fabrics, mesh, etc.—requires adaptable robotic grippers and advanced sensor technologies. Each material has different properties impacting grip, pressure, and manipulation.

- Dexterity Limitations: Achieving the precise level of dexterity required for tasks like lacing, knotting, and intricate stitching remains a significant challenge. Current robots often lack the fine motor control needed for these complex manipulations.

- Design and Size Variations: Sneaker designs vary greatly in style and complexity. Adapting robotic systems to handle these variations in design and size efficiently is crucial, but currently poses a significant hurdle. Programmable robots need flexible algorithms to accommodate these changes.

Programming and Integration Complexity

Integrating various robotic systems into a cohesive and efficient production line is a complex undertaking. This requires sophisticated programming and precise coordination.

- Adaptive Algorithms: Developing algorithms that allow robots to adapt to changing conditions, unexpected disruptions (e.g., material jams), and variations in workflow is essential for seamless operation.

- Inter-Robot Communication: Ensuring seamless communication between different robotic units and human operators is vital to avoid bottlenecks and production errors. This requires robust communication protocols and sophisticated control systems.

- High Integration Costs: The high cost of specialized programming and integration expertise significantly contributes to the overall complexity and financial investment required for robotic sneaker manufacturing.

Economic and Societal Implications of Automation

The introduction of robotics into sneaker manufacturing has profound economic and societal implications, raising important considerations.

Job Displacement Concerns

Automation inevitably raises concerns about job displacement for workers currently employed in sneaker factories.

- Reskilling and Retraining: Proactive reskilling and retraining initiatives are crucial to mitigate the negative impact on workers displaced by automation. Investing in programs that equip workers with new skills for roles in robotics maintenance, programming, or other related fields is essential.

- Increased Productivity and Lower Prices: The potential for increased productivity through automation could lead to significant cost savings, potentially resulting in lower prices for consumers.

- Ethical Considerations: A thoughtful discussion of the ethical implications of automation and its potential impact on employment is crucial. Balancing economic efficiency with social responsibility is vital for a just transition.

Return on Investment (ROI) and Cost Analysis

Implementing robotic systems requires a substantial upfront investment. A careful cost-benefit analysis is crucial to ensure a positive return on investment.

- Factors Affecting ROI: Several factors must be considered when calculating ROI, including production volume, the level of automation implemented, maintenance costs, and the cost of robotic system upgrades.

- Long-Term Cost Savings: The long-term cost savings from reduced labor costs and increased efficiency need to clearly outweigh the initial investment in robotics and associated infrastructure.

- Technological Advancements: Technological advancements are continuously driving down the cost of robotics, making automation increasingly economically feasible for companies like Nike.

The Future of Robotic Nike Sneaker Manufacturing

The future of robotic Nike sneaker manufacturing hinges on advancements in AI and collaborative human-robot systems.

Advancements in Artificial Intelligence (AI)

AI is poised to play a pivotal role in improving the efficiency and adaptability of robotic systems in sneaker manufacturing.

- Enhanced Precision and Speed: Machine learning algorithms can significantly enhance the precision and speed of robotic operations, leading to improved quality and output.

- Predictive Maintenance and Optimization: AI can optimize production processes by predicting potential problems, adapting to changing demands, and minimizing downtime through predictive maintenance.

- Advanced Sensor Technologies: The development of more sophisticated sensor technologies is crucial for enhancing robotic dexterity and precision, allowing for more complex manipulations.

Collaboration between Humans and Robots

The most effective approach likely involves a collaborative model, integrating the strengths of both human workers and robotic systems.

- Human Expertise and Problem-Solving: Humans can handle tasks requiring high levels of dexterity, creativity, problem-solving skills, and complex decision-making.

- Robots for Repetitive Tasks: Robots can effectively handle repetitive and physically demanding tasks, freeing up human workers to focus on more complex and value-added activities.

- Increased Efficiency and Quality: This collaborative approach holds the promise of significantly increased efficiency and higher-quality products.

Conclusion

Robotic Nike sneaker manufacturing presents both significant opportunities and considerable challenges. While technological hurdles related to precision, programming, and integration remain, the potential for increased efficiency, cost savings, and enhanced product quality is undeniable. The economic and societal implications, particularly concerning job displacement, require careful consideration and proactive solutions. The future likely lies in a collaborative approach, leveraging the strengths of both human expertise and advanced robotics.

Call to Action: To stay informed about the exciting developments and ongoing complexities in the field of robotic Nike sneaker manufacturing, continue exploring the latest research and advancements in automated shoe production. Understanding these intricacies is crucial for navigating the future of this dynamic industry and the evolving landscape of automated manufacturing.

Featured Posts

-

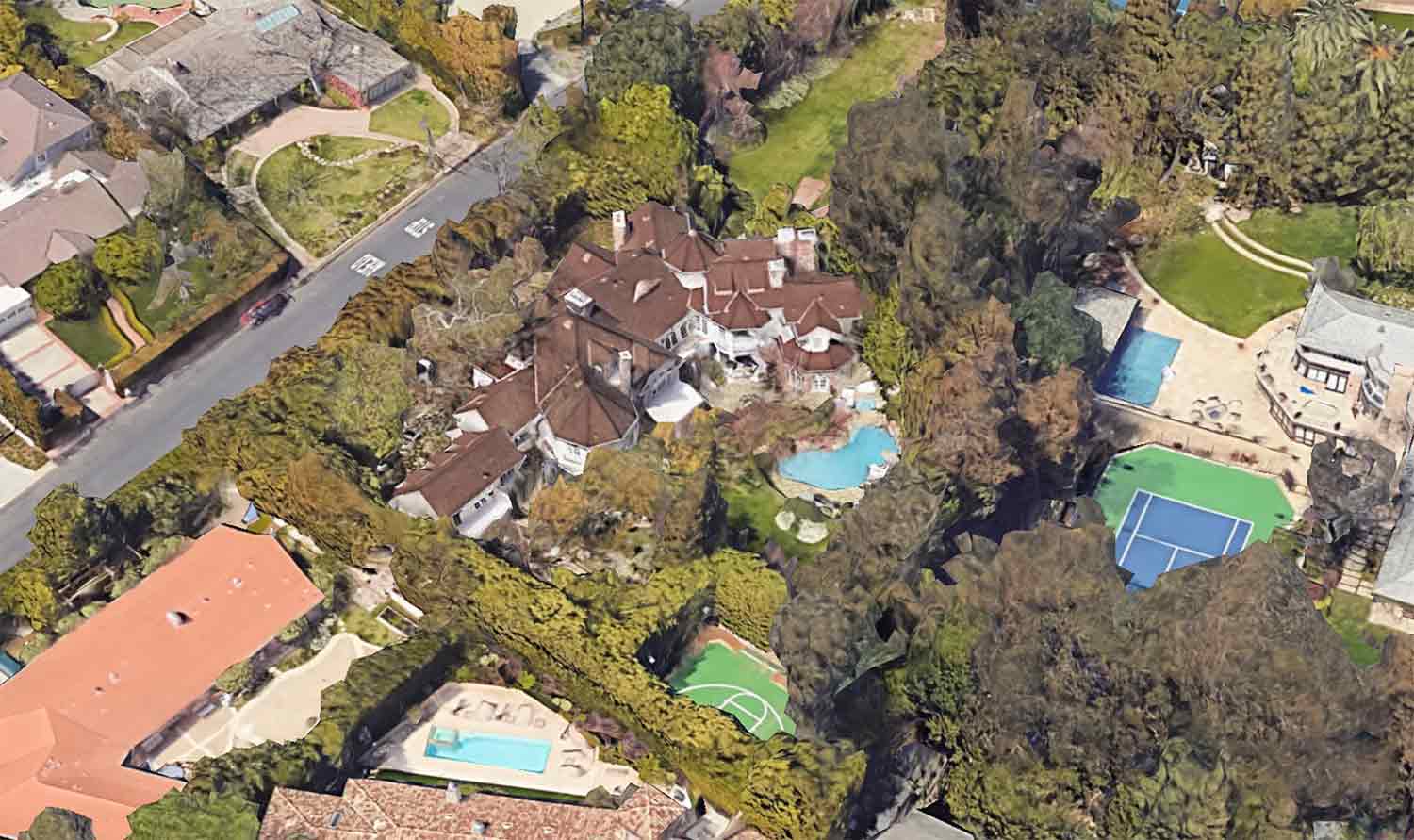

Celebrities Who Lost Homes In The La Palisades Fires A Complete List

Apr 22, 2025

Celebrities Who Lost Homes In The La Palisades Fires A Complete List

Apr 22, 2025 -

Trump Supporter Ray Epps Defamation Lawsuit Against Fox News Details Of The Jan 6th Case

Apr 22, 2025

Trump Supporter Ray Epps Defamation Lawsuit Against Fox News Details Of The Jan 6th Case

Apr 22, 2025 -

Razer Blade 16 2025 In Depth Review Of Ultra High Performance And Portability

Apr 22, 2025

Razer Blade 16 2025 In Depth Review Of Ultra High Performance And Portability

Apr 22, 2025 -

Saudi Aramco And Byd Partner To Explore Ev Technology

Apr 22, 2025

Saudi Aramco And Byd Partner To Explore Ev Technology

Apr 22, 2025 -

Understanding Papal Conclaves History Secrecy And The Election Of The Pope

Apr 22, 2025

Understanding Papal Conclaves History Secrecy And The Election Of The Pope

Apr 22, 2025

Latest Posts

-

Dakota Johnson Kraujingos Plintos Nuotraukos Kas Nutiko

May 10, 2025

Dakota Johnson Kraujingos Plintos Nuotraukos Kas Nutiko

May 10, 2025 -

Kto Je Slovenska Dakota Johnson

May 10, 2025

Kto Je Slovenska Dakota Johnson

May 10, 2025 -

Antipremiya Zolotaya Malina Kto Poluchil Nagrady Za Khudshie Roli I Filmy V 2023 Godu Vklyuchaya Dakotu Dzhonson

May 10, 2025

Antipremiya Zolotaya Malina Kto Poluchil Nagrady Za Khudshie Roli I Filmy V 2023 Godu Vklyuchaya Dakotu Dzhonson

May 10, 2025 -

Zolotaya Malina Dakota Dzhonson I Samye Provalnye Filmy Goda

May 10, 2025

Zolotaya Malina Dakota Dzhonson I Samye Provalnye Filmy Goda

May 10, 2025 -

Unlocking The Stock Market The Jazz Cash And K Trade Partnership

May 10, 2025

Unlocking The Stock Market The Jazz Cash And K Trade Partnership

May 10, 2025