Uncertainty And Trump's Tariffs: The Auto Industry's Dilemma

Table of Contents

The Impact of Tariffs on Auto Part Prices and Production Costs

Trump's tariffs dramatically increased the cost of imported auto parts, squeezing profit margins and disrupting established manufacturing processes. The tariffs weren't simply a blanket tax; they targeted specific materials and components crucial to automobile production. For example, the tariffs on steel and aluminum immediately impacted the cost of body panels and other structural components. Simultaneously, tariffs on electronic components sourced from Asia added another layer of increased expenses.

- Increased costs for steel and aluminum: The price of these essential materials surged, forcing automakers to absorb higher input costs or pass them onto consumers through increased vehicle prices.

- Higher prices for electronic components from Asia: Many advanced electronic components, essential for modern vehicles' functionality, originate in Asia. Tariffs on these parts significantly inflated manufacturing costs.

- Disruption of established supply chains: Years of carefully cultivated supply chain relationships were thrown into disarray. Automakers struggled to adapt to the new tariff landscape, leading to delays and production bottlenecks.

This confluence of factors had a devastating impact on manufacturing costs and profitability. Data from the industry shows a significant correlation between the implementation of tariffs and the rise in the cost of producing vehicles. The resulting pressure on profit margins forced automakers to re-evaluate their strategies, often leading to difficult decisions impacting employment and investment. Keywords like "import tariffs," "auto part costs," "manufacturing costs," and "supply chain disruption" highlight the severity of the situation.

Uncertainty and Investment Decisions in the Auto Industry

The fluctuating nature of Trump's trade policies created a climate of investment uncertainty that stifled long-term planning within the auto industry. Automakers, accustomed to making significant investments in new plants, research and development, and employee hiring based on long-term projections, found themselves paralyzed by unpredictable trade barriers.

- Delayed expansion projects: Major expansion plans were put on hold, as companies hesitated to commit vast sums of capital in the face of potentially crippling tariffs.

- Reduced R&D spending: Investment in crucial research and development, vital for innovation and future competitiveness, was scaled back as companies prioritized mitigating the immediate impact of tariffs.

- Hesitation in hiring new employees: The uncertainty surrounding future production costs made hiring decisions incredibly risky, leading to slower growth and a dampening effect on job creation.

This trade policy uncertainty had a chilling effect on auto industry investment and capital expenditure. The lack of visibility into future tariff policies made it impossible to accurately assess the long-term viability of various investment options. This hesitation had profound implications for the industry's competitiveness and ability to adapt to evolving market demands.

The Shifting Global Landscape and the Search for Alternatives

Faced with increased costs and production challenges, automakers were compelled to seek alternative sourcing strategies. This involved a complex and challenging process of adjusting global supply chains.

- Increased reliance on domestic suppliers: Automakers sought to bolster their relationships with domestic suppliers, but this often proved insufficient to fully offset the impact of tariffs on imported components.

- Negotiations with alternative international suppliers: Companies explored sourcing parts from countries not subject to the same tariffs, but this involved navigating new regulatory landscapes and establishing new supplier relationships.

- Exploration of new manufacturing locations: Some companies even considered relocating or expanding manufacturing operations to countries with more favorable trade relationships, a complex and costly undertaking.

This shift towards reshoring and nearshoring highlighted the interconnected nature of global supply chains. The difficulties encountered underscore the limitations of protectionist policies and the inherent challenges of rapidly reshaping complex and established supply networks.

The Case Studies of Specific Automakers

Several major automakers, including Ford and General Motors, publicly acknowledged the negative impact of Trump's tariffs on their operations. These companies implemented various mitigation strategies, ranging from increased domestic sourcing to adjustments in vehicle pricing. However, the overall experience demonstrated the significant disruption caused by the uncertainty and highlighted the challenges of adapting to rapidly changing trade landscapes.

Navigating the Aftermath of Uncertainty and Trump's Tariffs

In conclusion, Trump's tariffs created significant uncertainty, resulting in increased costs, investment hesitation, and substantial disruption to global supply chains within the auto industry. The impact extended beyond mere price increases; it undermined long-term planning and investment, hindering the industry's capacity for innovation and growth. The long-term implications for the industry's competitiveness remain a subject of ongoing analysis, but the experience underscores the crucial need for stable and predictable trade policies. To learn more about the far-reaching consequences of volatile trade policies on the auto sector, explore additional resources on the subject of uncertainty and Trump's tariffs. Engaging in discussions surrounding responsible and sustainable trade policy is essential to prevent similar economic uncertainties in the future.

Featured Posts

-

Eskort V Moskve Pochemu Kladovki Stali Novym Domom

May 02, 2025

Eskort V Moskve Pochemu Kladovki Stali Novym Domom

May 02, 2025 -

Nigel Farage And Rupert Lowe Their Public Feud Reaches A Boiling Point

May 02, 2025

Nigel Farage And Rupert Lowe Their Public Feud Reaches A Boiling Point

May 02, 2025 -

Fortnite 34 30 Release Date Maintenance And Early Patch Notes For Sabrina Carpenter Update

May 02, 2025

Fortnite 34 30 Release Date Maintenance And Early Patch Notes For Sabrina Carpenter Update

May 02, 2025 -

Severe Weather Timeline Strong Winds To Hit Oklahoma

May 02, 2025

Severe Weather Timeline Strong Winds To Hit Oklahoma

May 02, 2025 -

Georgia Stanway A Poignant Remembrance Of Young Girl Killed On Pitch

May 02, 2025

Georgia Stanway A Poignant Remembrance Of Young Girl Killed On Pitch

May 02, 2025

Latest Posts

-

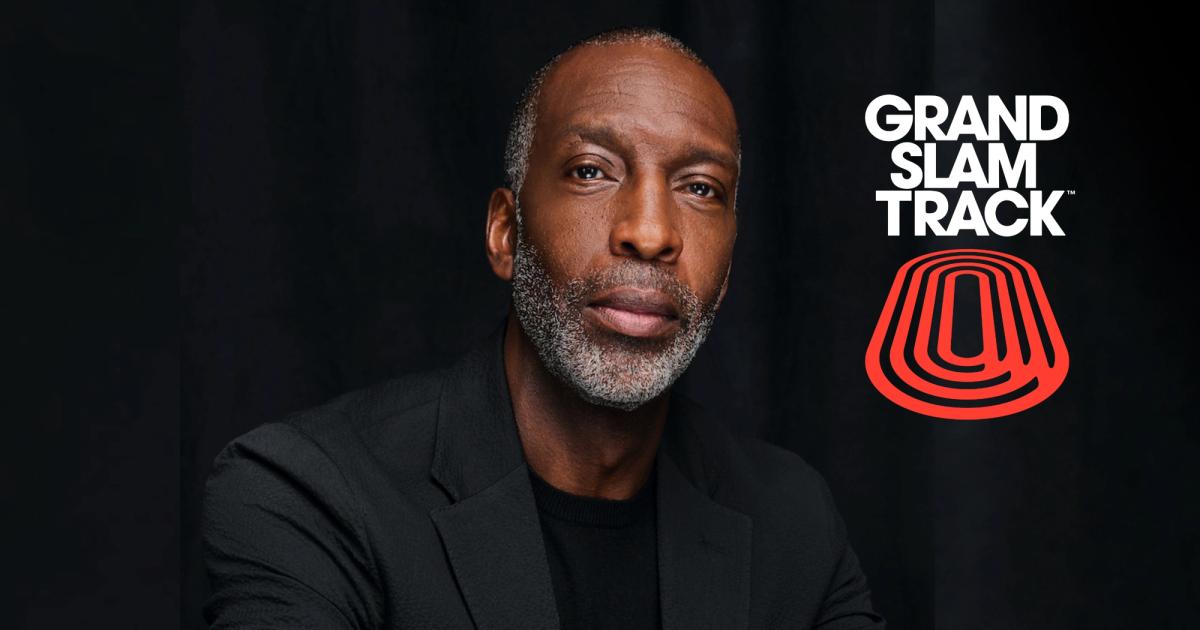

Grand Slam Track Meet Promises Speed Star Power And Significant Prize Money The Michael Johnson Effect

May 11, 2025

Grand Slam Track Meet Promises Speed Star Power And Significant Prize Money The Michael Johnson Effect

May 11, 2025 -

Ofilis Strong Showing Third Place Finish In 100 000 Grand Slam Race

May 11, 2025

Ofilis Strong Showing Third Place Finish In 100 000 Grand Slam Race

May 11, 2025 -

Michael Johnsons Grand Slam Track Meet Speed Star Power And Prize Money

May 11, 2025

Michael Johnsons Grand Slam Track Meet Speed Star Power And Prize Money

May 11, 2025 -

100 000 Grand Slam Debut Ofili Finishes Third

May 11, 2025

100 000 Grand Slam Debut Ofili Finishes Third

May 11, 2025 -

Grand Slam Track Revolutionizing The World Of Athletics

May 11, 2025

Grand Slam Track Revolutionizing The World Of Athletics

May 11, 2025