Upcoming Stadium Track Resurfacing: Ensuring A Smooth Championship Season

Table of Contents

Planning Your Stadium Track Resurfacing Project

Before any work begins, meticulous planning is key for successful stadium track resurfacing. This phase sets the foundation for a safe and high-performing track.

Assessing the Current Track Condition

A thorough assessment of the existing track is the first critical step. This involves identifying all areas of damage, wear, and potential hazards. Failing to conduct a proper assessment can lead to unforeseen complications and increased costs down the line.

- Conduct a visual inspection: Walk the entire track, noting cracks, holes, discoloration, and areas of significant wear.

- Utilize specialized track assessment tools: Employ tools like a surface profile meter to measure irregularities and identify areas requiring attention.

- Identify cracks, holes, and surface irregularities: Document the size, location, and severity of all defects. Pay close attention to areas with heavy athlete traffic.

- Document findings with photographs and reports: Create a comprehensive report with photos and detailed descriptions of the track's condition. This serves as a crucial reference point for the entire resurfacing process.

Choosing the Right Resurfacing Material

Selecting the appropriate resurfacing material significantly impacts the track's performance, longevity, and athlete safety. Different materials offer varying benefits depending on your specific needs and budget.

- Consider polyurethane, rubberized asphalt, or other specialized track surfaces: Each material has unique properties concerning durability, elasticity, and cost. Polyurethane, for example, is known for its excellent shock absorption, while rubberized asphalt offers a more cost-effective solution.

- Factor in budget, climate, and desired performance characteristics: Climate plays a crucial role; materials need to withstand extreme temperatures and weather conditions. Consider the level of performance required for your athletes – elite athletes may require a higher-performance material.

- Consult with track specialists and contractors for recommendations: Experienced professionals can offer valuable insights based on your specific needs and location. They can guide you towards the optimal material for your stadium track resurfacing project.

Securing Necessary Permits and Approvals

Before breaking ground, ensure all necessary permits and approvals are in place. This process can vary depending on your location, so it's crucial to start early.

- Check local building codes and regulations: Familiarize yourself with all relevant regulations and standards for track construction and resurfacing in your area.

- Contact relevant city or county departments: Obtain the necessary permits and approvals from the appropriate authorities, which may include planning departments, environmental agencies, and public works departments.

- Secure necessary environmental impact assessments if required: If your project necessitates environmental impact assessments, initiate these well in advance to avoid delays.

The Stadium Track Resurfacing Process

This phase involves the careful removal of the old surface, preparation of the base, and installation of the new track. Proper execution is crucial for a long-lasting and safe track.

Track Removal and Preparation

The existing track must be carefully removed without damaging the underlying base. This requires specialized equipment and expertise.

- Utilize proper demolition techniques to prevent damage to the base: Employ techniques that minimize damage to the sub-base, ensuring a stable foundation for the new surface. This may involve using specialized equipment and experienced personnel.

- Ensure proper grading and leveling of the base: A smooth and level base is crucial for a uniform track surface. This may require grading, compacting, and potentially repairing any underlying issues.

- Inspect and repair the sub-base if necessary: If cracks or other damage are found in the sub-base, repair them before installing the new track surface.

Installation of the New Track Surface

The new track surface is installed following the manufacturer's specifications and industry best practices. This ensures the track meets quality standards and provides optimal performance.

- Ensure proper curing time for the new surface: Allow sufficient time for the new surface to cure completely according to the manufacturer's instructions. Premature use can damage the track.

- Follow the manufacturer's instructions precisely: Adhere strictly to the manufacturer's guidelines regarding application techniques, thickness, and other critical aspects.

- Use specialized equipment for application and finishing: Employ the right equipment for spreading, compacting, and finishing the new track surface to ensure a smooth and even finish.

Quality Control and Inspection

Throughout the installation, rigorous quality control is essential. Regular inspections guarantee the project adheres to the highest standards.

- Regular inspections throughout the installation process: Conduct inspections at various stages of the installation to identify and address any problems early on.

- Use of appropriate testing equipment to ensure proper thickness and uniformity: Use specialized equipment to verify that the track meets the required thickness and is consistently smooth across the entire surface.

- Final inspection upon completion: A comprehensive final inspection verifies the new track meets all specifications and is ready for use.

Maintaining Your Newly Resurfaced Track

Proper maintenance after installation is critical for maximizing the lifespan and performance of your investment.

Post-Installation Care

The initial period after installation requires careful attention. Following the manufacturer's guidelines ensures the track cures correctly.

- Allow sufficient curing time: Do not allow any use of the track until the manufacturer's specified curing time has elapsed.

- Avoid heavy use immediately after completion: Restrict use for the first few days to allow the surface to fully cure and harden.

- Follow manufacturer's recommendations for cleaning and maintenance: The manufacturer's guidelines will outline the best practices for cleaning and maintaining your specific track material.

Regular Cleaning and Maintenance

Regular cleaning and maintenance prevent the accumulation of dirt, debris, and other contaminants.

- Sweep and remove debris regularly: Regular sweeping removes dirt, leaves, and other debris that could damage the track surface.

- Address minor damage promptly: Repair small cracks or other minor damages immediately to prevent them from worsening.

- Implement a regular inspection schedule: Conduct routine inspections to identify potential issues early on.

Long-Term Track Preservation Strategies

Proactive measures extend the life and performance of your stadium track resurfacing investment significantly.

- Develop a long-term maintenance plan: Create a comprehensive maintenance schedule outlining regular cleaning, inspections, and repairs.

- Budget for periodic repairs and maintenance: Allocate resources for routine maintenance and occasional repairs to prevent major issues from arising.

- Monitor the track condition closely: Regularly monitor the track for any signs of wear and tear to address problems promptly.

Conclusion

Successfully completing a stadium track resurfacing project requires careful planning, execution, and ongoing maintenance. By following the steps outlined in this article, you can ensure a smooth, safe, and high-performing track for your championship season. Don't let a substandard track jeopardize your athletes' performance or safety; invest in professional stadium track resurfacing today! Contact a reputable track contractor now to discuss your resurfacing needs and secure a successful championship season.

Featured Posts

-

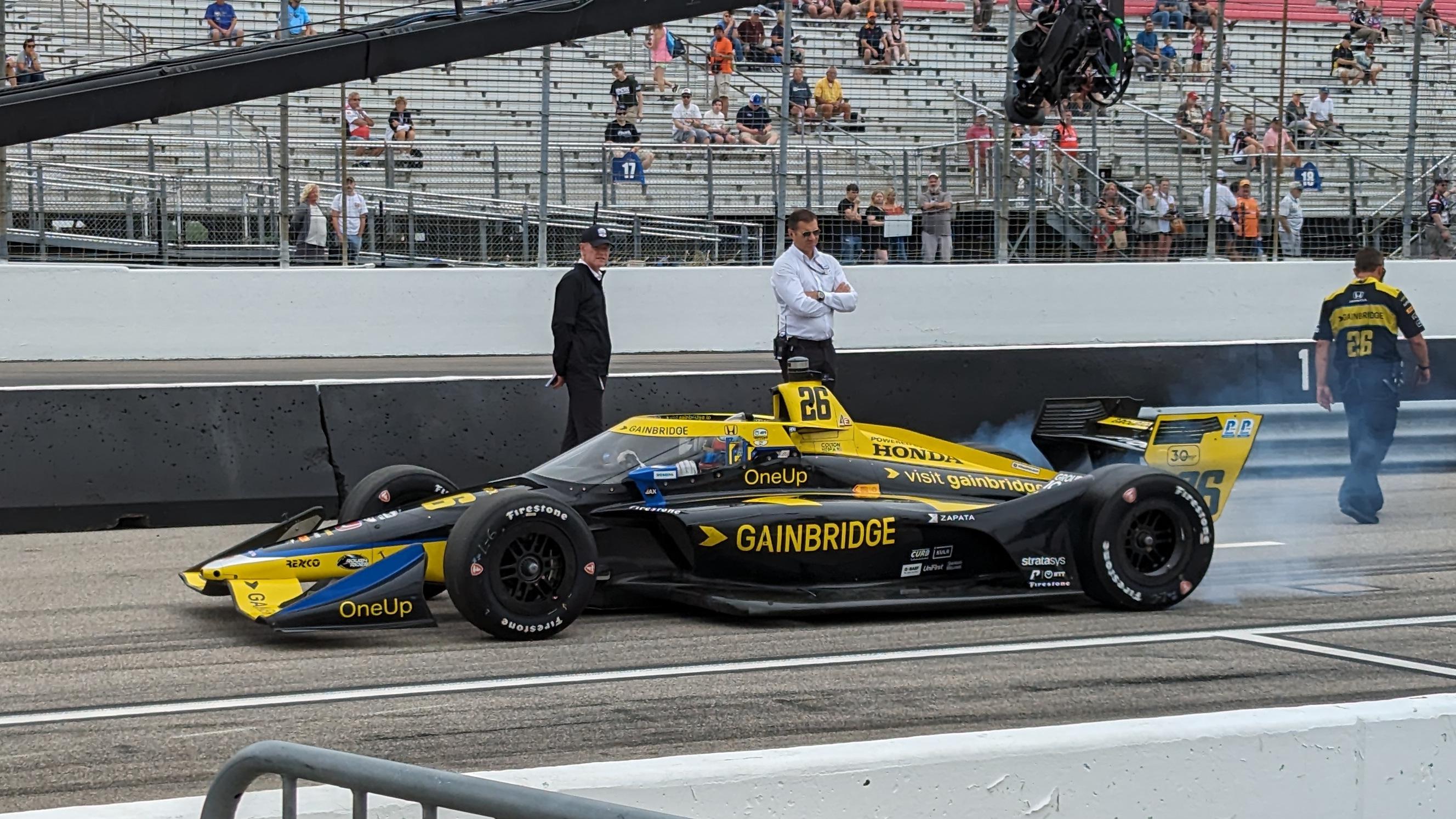

Indy Car At Barber Colton Hertas Quest For Qualifying Pace

May 12, 2025

Indy Car At Barber Colton Hertas Quest For Qualifying Pace

May 12, 2025 -

Jessica Simpson Returns To The Stage After 15 Years Fan Reactions And Highlights

May 12, 2025

Jessica Simpson Returns To The Stage After 15 Years Fan Reactions And Highlights

May 12, 2025 -

Tom Cruises Unique Post Birth Gesture For Suri Cruise

May 12, 2025

Tom Cruises Unique Post Birth Gesture For Suri Cruise

May 12, 2025 -

Max Greenlights New Projects Based On Crazy Rich Asians Franchise Jon M Chu To Oversee

May 12, 2025

Max Greenlights New Projects Based On Crazy Rich Asians Franchise Jon M Chu To Oversee

May 12, 2025 -

Crazy Rich Asians Tv Adaptation Details On The Upcoming Series

May 12, 2025

Crazy Rich Asians Tv Adaptation Details On The Upcoming Series

May 12, 2025

Latest Posts

-

Open Ai Facing Ftc Investigation A Deep Dive Into The Potential Consequences

May 12, 2025

Open Ai Facing Ftc Investigation A Deep Dive Into The Potential Consequences

May 12, 2025 -

Assessing The Outcomes How Markets React To The Latest Us China Trade Negotiations

May 12, 2025

Assessing The Outcomes How Markets React To The Latest Us China Trade Negotiations

May 12, 2025 -

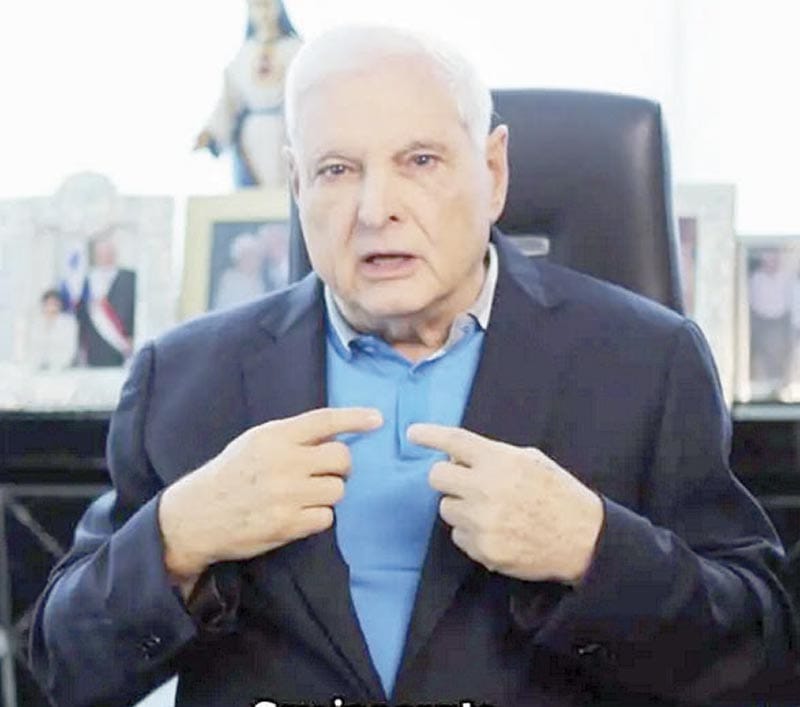

Colombia Acoge A Ricardo Martinelli Detalles Del Asilo

May 12, 2025

Colombia Acoge A Ricardo Martinelli Detalles Del Asilo

May 12, 2025 -

India Confirms Five Soldier Deaths Amidst Continued India Pakistan Truce

May 12, 2025

India Confirms Five Soldier Deaths Amidst Continued India Pakistan Truce

May 12, 2025 -

Anchor Brewing A Look Back At 127 Years Of Brewing History And Its Upcoming Closure

May 12, 2025

Anchor Brewing A Look Back At 127 Years Of Brewing History And Its Upcoming Closure

May 12, 2025