Workboat Automation: TBS Safety And Nebofleet Collaboration

Table of Contents

Enhancing Workboat Safety through Automation with TBS Safety

TBS Safety is at the forefront of developing innovative solutions to enhance workboat safety. Their automation technologies provide a proactive and reactive approach to risk management, significantly reducing the potential for accidents and improving emergency response capabilities.

Improved Risk Management and Prevention

TBS Safety's systems offer proactive risk assessment and mitigation through:

- Real-time monitoring: Continuous monitoring of critical vessel systems, identifying potential issues before they escalate into emergencies.

- Predictive maintenance alerts: Automated alerts based on data analysis, enabling preventative maintenance and reducing downtime caused by unexpected equipment failures.

- Automated safety checks: Automated checklists and inspections ensure consistent adherence to safety protocols, minimizing human error.

- Data-driven insights: Comprehensive data analysis provides valuable insights into safety trends, enabling operators to identify and address potential hazards proactively and improve safety protocols.

By automating these processes, TBS Safety reduces human error, a leading cause of accidents in the maritime industry, and improves response times to potential hazards, leading to safer working conditions for crews. For example, automated alerts for engine overheating can prevent catastrophic engine failure, while real-time monitoring of crew location during an emergency can drastically reduce rescue times.

Real-time Monitoring and Emergency Response

In the event of an emergency, TBS Safety's technology facilitates efficient communication and response:

- Automated distress signals: Automatic transmission of distress signals to relevant authorities, ensuring rapid response in critical situations.

- Location tracking: Precise vessel location tracking enables swift mobilization of rescue teams.

- Crew communication systems: Integrated communication systems maintain clear communication between crew members and shore-based teams.

- Integration with emergency services: Seamless integration with emergency response services streamlines the process of obtaining assistance.

Case studies demonstrate significant reductions in response times and improved outcomes in emergency situations thanks to these automated systems. For instance, one case study showed a 30% reduction in response time for distress calls after implementing TBS Safety's automated system.

Compliance and Regulatory Adherence

Meeting stringent maritime regulations is crucial for workboat operators. TBS Safety's automated systems simplify compliance:

- Automated logbook entries: Automated recording of essential operational data, eliminating manual errors and saving valuable time.

- Data recording for audits: Organized data storage and retrieval simplifies audits and inspections, ensuring compliance with regulatory requirements.

- Compliance reporting tools: Automated generation of compliance reports ensures efficient and accurate reporting to relevant authorities.

These features help workboats easily meet standards set by organizations like the IMO (International Maritime Organization) and national maritime agencies.

Optimizing Workboat Efficiency with Nebofleet's Automation Solutions

Nebofleet provides a comprehensive platform for optimizing workboat operations through automation. Their solutions enhance fleet management, improve decision-making, and lead to significant cost savings.

Fleet Management and Optimization

Nebofleet's platform empowers operators to effectively manage their fleets and allocate resources:

- Real-time vessel tracking: Continuous monitoring of vessel locations, enhancing situational awareness and enabling proactive adjustments to schedules.

- Route optimization: Sophisticated algorithms identify the most efficient routes, minimizing fuel consumption and travel times.

- Fuel consumption monitoring: Detailed fuel consumption data identifies areas for improvement and facilitates cost reduction strategies.

- Predictive maintenance scheduling: Data-driven predictions enable preventative maintenance, minimizing downtime and extending equipment lifespan.

This translates to substantial cost savings through reduced fuel consumption, optimized routing, and minimized maintenance disruptions.

Data-Driven Decision Making

Nebofleet leverages data analytics to provide actionable insights for improved decision-making:

- Performance analysis: Comprehensive performance data identifies areas for efficiency improvement and allows for informed adjustments to operational strategies.

- Operational reporting: Automated reports provide clear insights into operational performance, allowing for tracking of key metrics.

- Identification of areas for improvement: Data analysis highlights areas where operational inefficiencies exist, enabling targeted interventions.

These data-driven insights empower operators to make strategic decisions, leading to improved operational efficiency and profitability.

Seamless Integration with TBS Safety Systems

The synergy between Nebofleet and TBS Safety creates a powerful combination:

- Unified data platform: Integrated data sharing between both systems provides a holistic view of vessel operations, enhancing both safety and efficiency.

- Improved communication: Streamlined communication between safety and operational teams improves response times and collaboration.

- Enhanced safety and efficiency: Combined functionalities create a synergistic effect, leading to significant improvements in both safety and efficiency.

This unified approach provides a holistic and comprehensive management solution, maximizing the benefits of workboat automation.

The Synergistic Partnership: TBS Safety and Nebofleet Collaboration

The collaboration between TBS Safety and Nebofleet represents a powerful force in advancing workboat automation.

Combined Strengths for Enhanced Workboat Operations

The complementary nature of their technologies offers a significant advantage:

- Improved safety: Enhanced risk management, proactive monitoring, and efficient emergency response significantly improve overall safety.

- Increased efficiency: Optimized fleet management, reduced downtime, and data-driven decision-making increase operational efficiency.

- Reduced operational costs: Minimized fuel consumption, preventative maintenance, and improved resource allocation lead to significant cost savings.

- Enhanced compliance: Automated compliance reporting and data logging ensure adherence to all relevant regulations.

This holistic approach transforms workboat management from reactive to proactive, ensuring safer, more efficient, and more profitable operations.

Future Innovations and Developments

The partnership between TBS Safety and Nebofleet paves the way for exciting advancements in workboat automation:

- AI-powered predictive maintenance: Artificial intelligence will further enhance predictive maintenance capabilities, minimizing downtime and maximizing equipment lifespan.

- Autonomous navigation systems: Future integrations may incorporate autonomous navigation systems, further enhancing efficiency and safety.

- Further integration of technologies: Ongoing collaboration will result in deeper integration of technologies, creating an even more seamless and comprehensive workboat management platform.

The future of workboat operations is bright, with automation leading the way towards safer, more efficient, and more sustainable practices.

The Future of Workboat Operations is Automated: TBS Safety and Nebofleet Leading the Way

The collaboration between TBS Safety and Nebofleet is revolutionizing the workboat industry. By combining their expertise in safety and operational efficiency, they offer a comprehensive solution that significantly improves safety protocols, optimizes resource allocation, and ensures regulatory compliance. The resulting benefits include reduced operational costs, enhanced crew safety, and improved overall profitability. Learn more about how workboat automation, powered by the TBS Safety and Nebofleet partnership, can transform your operations. Visit our websites today to discover the possibilities!

Featured Posts

-

Fortnite Update 34 30 Downtime Schedule And Whats New

May 02, 2025

Fortnite Update 34 30 Downtime Schedule And Whats New

May 02, 2025 -

Islas Fight Sounesss Swim A Testament To Courage And Determination

May 02, 2025

Islas Fight Sounesss Swim A Testament To Courage And Determination

May 02, 2025 -

Onde Comprar Mini Camera Chaveiro Melhores Lojas Online

May 02, 2025

Onde Comprar Mini Camera Chaveiro Melhores Lojas Online

May 02, 2025 -

Analyzing Rupert Lowes X Post Effectiveness Of Messaging In The Uk Reform Debate

May 02, 2025

Analyzing Rupert Lowes X Post Effectiveness Of Messaging In The Uk Reform Debate

May 02, 2025 -

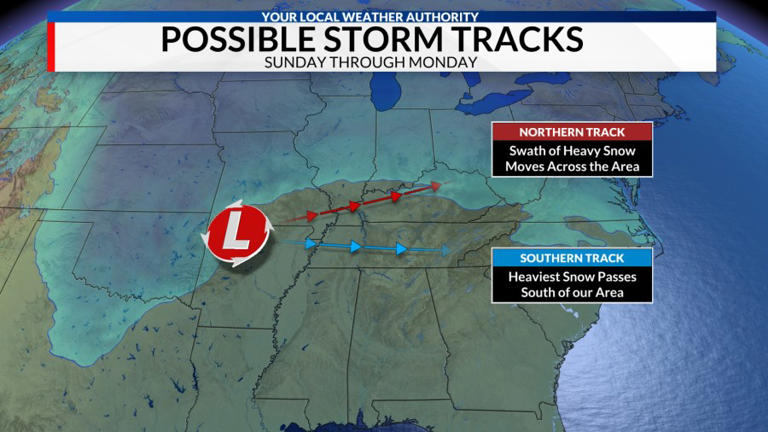

Tuesdays Snowstorm Four Inches Plus Expected Bitter Cold Temperatures Predicted

May 02, 2025

Tuesdays Snowstorm Four Inches Plus Expected Bitter Cold Temperatures Predicted

May 02, 2025

Latest Posts

-

Proces Pour Violences Conjugales A Dijon Le Boxeur Bilel Latreche Convoque

May 10, 2025

Proces Pour Violences Conjugales A Dijon Le Boxeur Bilel Latreche Convoque

May 10, 2025 -

Violences Conjugales A Dijon Le Boxeur Bilel Latreche Devant La Justice En Aout

May 10, 2025

Violences Conjugales A Dijon Le Boxeur Bilel Latreche Devant La Justice En Aout

May 10, 2025 -

Dijon Bilel Latreche Boxeur Accuse De Violences Conjugales Comparaitra En Aout

May 10, 2025

Dijon Bilel Latreche Boxeur Accuse De Violences Conjugales Comparaitra En Aout

May 10, 2025 -

Municipales Dijon 2026 Un Programme Ecologique Pour La Ville

May 10, 2025

Municipales Dijon 2026 Un Programme Ecologique Pour La Ville

May 10, 2025 -

Dijon Psg Le Club De La Capitale S Impose En Arkema Premiere Ligue

May 10, 2025

Dijon Psg Le Club De La Capitale S Impose En Arkema Premiere Ligue

May 10, 2025