Trump's Tariffs: Automakers Struggle With Uncertainty

Table of Contents

Increased Import Costs and Reduced Competitiveness

Trump's tariffs, particularly those targeting steel and aluminum, dramatically increased production costs for automakers. The impact of these automotive tariffs extended far beyond the initial imposition of duties; the ripple effect was felt throughout the entire supply chain.

- Tariff impact on input costs: Tariffs on imported steel and aluminum, key components in vehicle manufacturing, significantly increased input costs. This directly translated to higher manufacturing costs for every vehicle produced.

- Escalating vehicle prices: Higher production costs inevitably led to increased vehicle prices, making cars less affordable for consumers and dampening demand. This price increase impacted both domestic and imported vehicles.

- Competitive disadvantage for foreign automakers: Foreign automakers operating in the US market faced a significant competitive disadvantage. The tariffs raised their manufacturing costs, making their vehicles less price-competitive against domestically produced cars.

- Disproportionate impact on smaller automakers: Smaller automakers with less negotiating power and leverage were disproportionately affected by the increased import costs. Larger manufacturers often had more resources to absorb the cost increases or negotiate better deals with suppliers.

The specific financial impact varied across automakers, with some absorbing the costs through reduced profit margins while others passed the increased costs directly to consumers through higher prices. Analysis of financial reports from this period reveals a clear correlation between the imposition of tariffs and the reduction in profitability for many automotive manufacturers. The competitive landscape shifted, with some manufacturers better positioned to weather the storm than others.

Disruption of Global Supply Chains

The Trump tariffs significantly disrupted global supply chains within the automotive industry, creating logistical nightmares and manufacturing delays. The complexities of international trade became even more pronounced, forcing automakers to reassess their sourcing strategies.

- Complicated parts sourcing: International sourcing of automotive parts became significantly more complicated and expensive. The added tariffs made importing components from traditional suppliers more costly, potentially delaying production.

- Discouraged long-term investment: The uncertainty surrounding future tariffs and trade policies discouraged long-term investment in global supply chains. Automakers hesitated to commit to long-term contracts or build new facilities in uncertain trade environments.

- Search for alternative suppliers: Automakers were forced to explore alternative suppliers, often located closer to home or in countries with more favorable trade agreements. This often resulted in higher costs and potentially lower quality components.

- Increased logistical challenges: Navigating the shifting trade regulations and increased customs procedures added significant logistical challenges and administrative overhead. The increased complexity impacted shipping times, leading to production delays.

Case studies from this era illustrate the substantial disruptions experienced by various automakers. Many companies reported delays in production and increased costs due to difficulties in sourcing parts efficiently. This highlights the vulnerability of globally integrated supply chains to sudden shifts in trade policy.

Restructuring and Relocation

In response to increased costs and trade uncertainty, some automakers initiated significant restructuring measures, including factory closures and plant relocations.

- Operational restructuring: Many automakers responded to the pressure by restructuring their operations, streamlining production processes, and seeking ways to reduce costs. This often involved layoffs and workforce reductions.

- Factory closures and relocations: Some automakers considered, and in some cases implemented, factory closures and plant relocations to countries with more favorable trade environments or lower labor costs.

- Delayed or altered investment decisions: The unpredictable trade environment led to delays or alterations in planned investments in new facilities, research and development, and equipment upgrades. Uncertainty discouraged long-term commitments.

- Long-term economic impact: The long-term effects on employment and economic growth in affected regions are still being assessed. Factory closures and job losses had significant local economic consequences.

These decisions had profound implications for employment and local economies. The relocation of manufacturing facilities to other countries resulted in job losses in the US and other affected regions. The long-term social and economic consequences are multifaceted and complex.

Consumer Impact and Market Adjustments

The increased costs resulting from Trump's tariffs ultimately impacted consumers through higher car prices and market adjustments.

- Reduced consumer demand: Higher car prices directly reduced consumer demand, leading to lower overall sales figures across the automotive industry. Consumers delayed purchases or opted for cheaper alternatives.

- Shifted market share: Automakers with better ability to absorb increased costs or those with stronger domestic supply chains gained a competitive advantage and saw a shift in their market share.

- Long-term impact on consumer confidence: The long-term effects on consumer confidence and purchasing habits require further investigation. The uncertainty created by fluctuating trade policies could have lasting impacts on consumer spending.

- Complex macroeconomic implications: The overall impact on the American economy was complex and multifaceted. The reduced consumer spending and potential job losses had wide-ranging consequences for the broader economic landscape.

The automotive sector’s performance became a microcosm of the larger macroeconomic environment, reflecting the broader impact of the trade policies on the US economy. The interplay between supply, demand, and consumer confidence was significantly impacted by the uncertainty caused by the tariffs.

Conclusion

Trump's tariffs presented significant challenges for automakers, leading to increased costs, supply chain disruptions, and market adjustments. The long-term consequences are still unfolding, underscoring the importance of stable and predictable trade policies for the global automotive industry. Understanding the impact of Trump's tariffs on the auto industry is crucial for navigating future trade uncertainties. Continue reading to delve deeper into the specific effects of these tariffs on various automakers and their strategies for adapting to the changing global market and understanding the complexities of future Trump tariffs and their potential impact on the automotive industry.

Featured Posts

-

School Suspensions Do The Risks Outweigh The Benefits

May 02, 2025

School Suspensions Do The Risks Outweigh The Benefits

May 02, 2025 -

Boj Slashes Growth Forecast Trade Tensions Dampen Economic Prospects

May 02, 2025

Boj Slashes Growth Forecast Trade Tensions Dampen Economic Prospects

May 02, 2025 -

Google Search Facing Extinction Sundar Pichais Doj Antitrust Concerns

May 02, 2025

Google Search Facing Extinction Sundar Pichais Doj Antitrust Concerns

May 02, 2025 -

Declan Rice Souness Highlights Key Area For Improvement To Achieve World Class Level

May 02, 2025

Declan Rice Souness Highlights Key Area For Improvement To Achieve World Class Level

May 02, 2025 -

Israil Parlamentosu Nda Esir Aileleri Ile Guevenlik Guecleri Arasindaki Gerginlik

May 02, 2025

Israil Parlamentosu Nda Esir Aileleri Ile Guevenlik Guecleri Arasindaki Gerginlik

May 02, 2025

Latest Posts

-

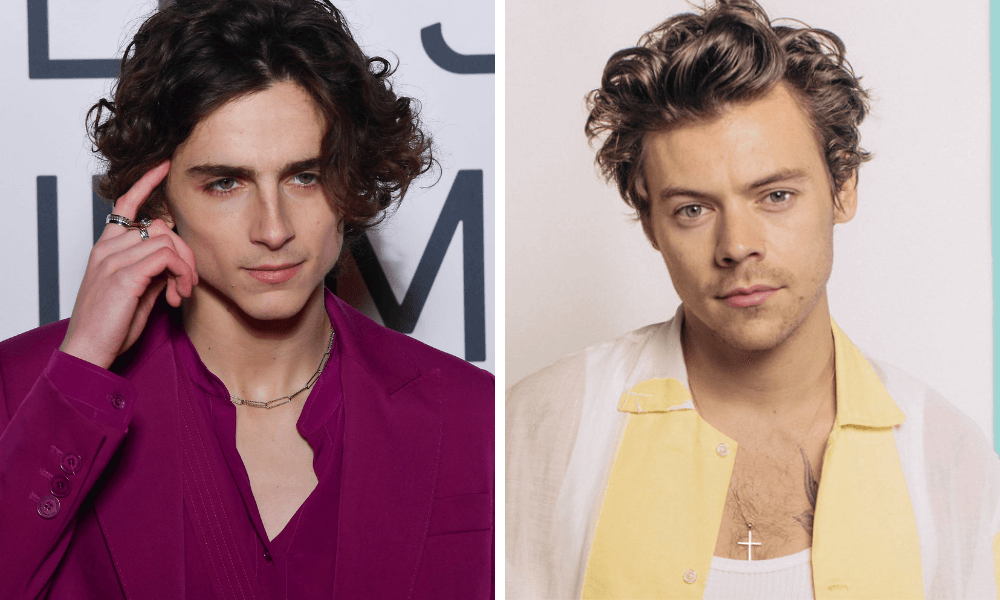

The Harry Styles Influence On Benson Boone Fact Or Fiction

May 10, 2025

The Harry Styles Influence On Benson Boone Fact Or Fiction

May 10, 2025 -

Benson Boone Vs Harry Styles A Look At The Sound Alike Claims

May 10, 2025

Benson Boone Vs Harry Styles A Look At The Sound Alike Claims

May 10, 2025 -

Snls Bad Harry Styles Impression How He Really Felt

May 10, 2025

Snls Bad Harry Styles Impression How He Really Felt

May 10, 2025 -

Addressing The Controversy Benson Boone And The Harry Styles Comparisons

May 10, 2025

Addressing The Controversy Benson Boone And The Harry Styles Comparisons

May 10, 2025 -

Is Benson Boone Copying Harry Styles The Singers Response

May 10, 2025

Is Benson Boone Copying Harry Styles The Singers Response

May 10, 2025