Overcoming The Challenges Of Robotic Nike Sneaker Manufacturing

Table of Contents

Precision and Dexterity Challenges in Robotic Sneaker Assembly

Replicating the dexterity of human hands in robotic systems for sneaker assembly poses a significant hurdle. Tasks such as attaching delicate laces, stitching intricate patterns, and handling diverse materials like leather, mesh, and suede require a level of fine motor skill and adaptability currently beyond the capabilities of most robots. This necessitates the development of highly sophisticated robotic systems.

- Challenges in handling varying material thicknesses and flexibilities: Sneakers are composed of various materials with different thicknesses and flexibilities, demanding robots with adaptable grippers and manipulation strategies.

- Need for advanced sensors and AI-powered vision systems for precise placement and alignment: Precise placement of components requires advanced sensor technology and AI-driven vision systems to ensure accurate alignment and avoid errors.

- Development of soft robotics and adaptable grippers for better manipulation: Soft robotics, incorporating flexible materials and actuators, shows promise in improving the dexterity and adaptability of robotic systems for handling delicate components.

- The high cost associated with developing such sophisticated robotic systems: The development of these advanced robotic systems involves substantial research and development costs, contributing significantly to the overall investment.

Programming and Integration Complexity for Robotic Shoe Production

Programming robots for the numerous steps involved in sneaker manufacturing is incredibly complex. It requires sophisticated software capable of handling variations in shoe designs, sizes, and material combinations. Seamless integration of various robotic systems and software is crucial for efficient operation.

- The need for sophisticated programming to handle variations in shoe designs and sizes: Each sneaker model presents unique assembly challenges, demanding flexible and adaptable robotic programming.

- Challenges in coordinating multiple robots working simultaneously on a single shoe: Optimizing the collaboration of multiple robots on an assembly line requires complex coordination algorithms and communication protocols.

- Integration with existing manufacturing infrastructure and legacy systems: Integrating robotic systems into existing factories often involves significant modifications and adaptations to the existing infrastructure and legacy systems.

- The need for skilled programmers and technicians to maintain and troubleshoot the systems: Maintaining and troubleshooting complex robotic systems necessitates a skilled workforce proficient in robotics programming, maintenance, and repair.

Cost-Effectiveness and Return on Investment (ROI) of Robotic Sneaker Manufacturing

While robotic automation offers the potential for long-term cost savings through reduced labor costs and increased efficiency, the initial investment is substantial. A comprehensive analysis of the cost-effectiveness and return on investment (ROI) is crucial for justifying the adoption of robotic systems.

- High upfront costs of robotic equipment and software: The purchase and installation of advanced robotic equipment and software represent a significant upfront investment.

- Ongoing maintenance and repair expenses: Maintaining and repairing complex robotic systems involves ongoing costs.

- Need for skilled labor for programming, operation, and maintenance: The operation and maintenance of robotic systems require specialized personnel, adding to the operational costs.

- Potential for increased efficiency and reduced waste, leading to long-term cost savings: Despite the initial investment, the increased efficiency and reduced waste resulting from automation can lead to considerable long-term cost savings.

Addressing Ethical Considerations and Job Displacement in Automated Shoe Manufacturing

The automation of sneaker manufacturing raises ethical considerations, primarily concerning the potential for job displacement. Mitigating the negative social impact of automation is crucial for responsible technological advancement.

- Potential job losses in manual labor roles: Automation inevitably leads to job displacement in some manual labor roles.

- The need for worker retraining and upskilling programs: Retraining and upskilling programs are essential to help displaced workers transition to new roles.

- Importance of transparent communication with employees: Open and honest communication with employees is vital to addressing concerns and building trust.

- Focus on creating new roles in areas such as robotics programming, maintenance, and AI development: Automation creates opportunities for new roles focused on the design, implementation, and maintenance of robotic systems.

Conclusion

Overcoming the challenges of robotic Nike sneaker manufacturing requires addressing both technical and ethical considerations. The high initial investment, complexities in programming and integration, and the need for precision and dexterity in robotic systems are significant hurdles. However, the potential for increased efficiency, reduced costs, and innovative production methods makes continued investment in this area essential. The future of Nike sneaker manufacturing, and the broader footwear industry, hinges on successfully overcoming these challenges. Stay informed about the latest developments in robotic Nike sneaker manufacturing to understand how this innovative technology will shape the industry.

Featured Posts

-

How Middle Management Drives Company Performance And Employee Engagement

Apr 22, 2025

How Middle Management Drives Company Performance And Employee Engagement

Apr 22, 2025 -

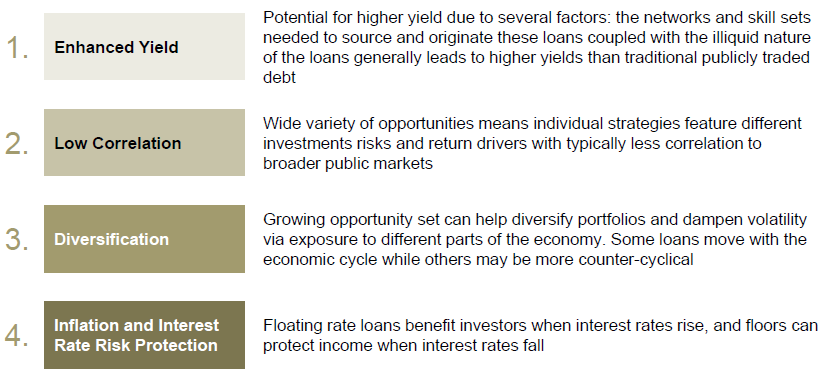

5 Dos And Don Ts For Landing A Private Credit Job

Apr 22, 2025

5 Dos And Don Ts For Landing A Private Credit Job

Apr 22, 2025 -

Identifying The Countrys Top New Business Locations

Apr 22, 2025

Identifying The Countrys Top New Business Locations

Apr 22, 2025 -

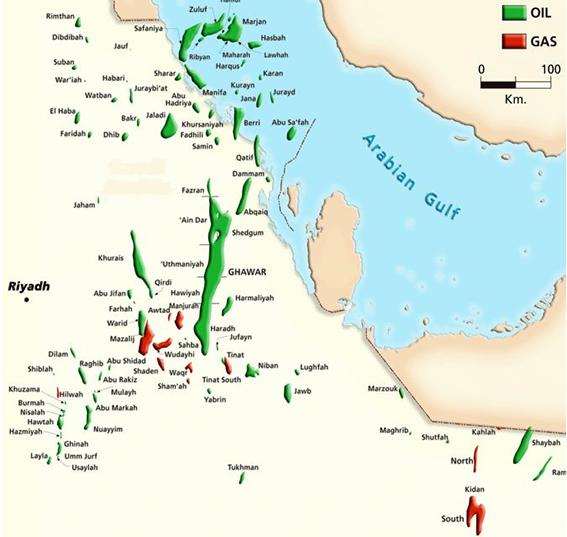

New Ev Technology Exploration Saudi Aramco And Byds Strategic Partnership

Apr 22, 2025

New Ev Technology Exploration Saudi Aramco And Byds Strategic Partnership

Apr 22, 2025 -

Hegseths Signal Chats Military Plans Discussed With Family

Apr 22, 2025

Hegseths Signal Chats Military Plans Discussed With Family

Apr 22, 2025

Latest Posts

-

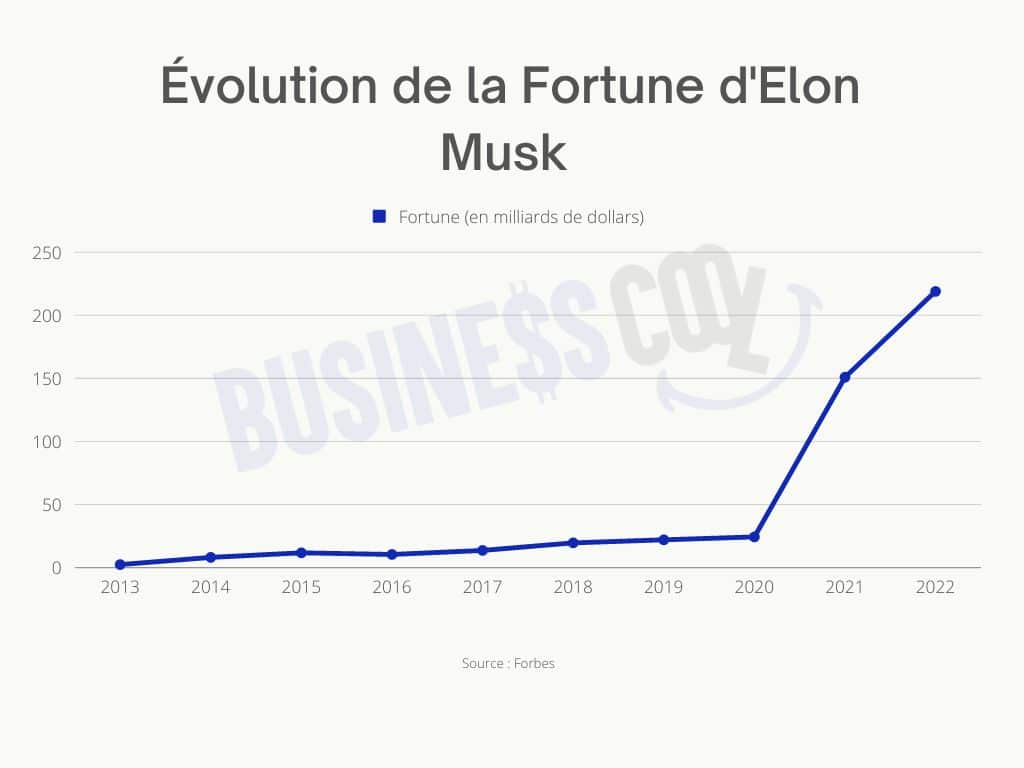

Elon Musks Path To Riches Key Investments And Entrepreneurial Strategies

May 10, 2025

Elon Musks Path To Riches Key Investments And Entrepreneurial Strategies

May 10, 2025 -

The Economic Impact Of Post Liberation Day Tariffs On Trumps Billionaire Circle

May 10, 2025

The Economic Impact Of Post Liberation Day Tariffs On Trumps Billionaire Circle

May 10, 2025 -

The Elon Musk Fortune Examining The Business Strategies Of The Worlds Richest Man

May 10, 2025

The Elon Musk Fortune Examining The Business Strategies Of The Worlds Richest Man

May 10, 2025 -

Liberation Day Tariffs The Financial Fallout For Trumps Wealthy Associates

May 10, 2025

Liberation Day Tariffs The Financial Fallout For Trumps Wealthy Associates

May 10, 2025 -

Elon Musks Financial Empire From Pay Pal To Space X And Beyond

May 10, 2025

Elon Musks Financial Empire From Pay Pal To Space X And Beyond

May 10, 2025