The Difficult Path To Robotic Nike Shoe Production

Table of Contents

The Complexity of Shoe Manufacturing for Robots

Shoe manufacturing is a surprisingly complex process, far more intricate than many automated industries. Robots struggle with the nuanced tasks involved in creating a single pair of shoes. The process encompasses a variety of steps, each presenting unique challenges for robotic automation. Consider the following:

-

Diverse Materials: Shoes utilize a wide range of materials, from supple leather and durable synthetics to flexible textiles. Each material requires different handling techniques, making it difficult for robotic grippers to maintain a consistent grip and avoid damage. This necessitates the development of highly adaptable and sophisticated robotic end-effectors.

-

Precise Assembly: Creating a shoe involves precise stitching, gluing, and the assembly of numerous components. Achieving the necessary dexterity and force control for these tasks remains a significant challenge for robots. The delicate nature of some materials further complicates the process, demanding high levels of accuracy to avoid tearing or misalignment.

-

Intricate Designs and Sizes: Nike produces shoes in countless styles, colors, and sizes, each with unique design features and assembly requirements. This variability requires adaptable robotic systems capable of handling a wide range of designs and dimensions. Programmable robotic arms are essential, but creating the adaptable software presents a significant challenge.

-

Quality Control: Ensuring consistent quality is crucial in shoe manufacturing. Current robotic systems struggle with reliable quality control and defect detection, requiring significant advancements in sensor technology and image processing to identify imperfections efficiently. This requires advanced computer vision systems and machine learning to effectively identify even subtle defects.

Technological Hurdles in Robotic Shoe Production

The technological barriers to robotic shoe production are substantial. While advancements in robotics are rapid, the precision and adaptability required for complex shoe assembly are still largely unmet. Key technological hurdles include:

-

Artificial Intelligence (AI) and Machine Learning (ML): Developing robust AI algorithms that allow robots to make real-time decisions during assembly is crucial. These algorithms must account for variations in materials, designs, and sizes, allowing the robots to adapt and adjust their actions dynamically. Machine learning is critical to improve performance over time.

-

Computer Vision: Reliable computer vision systems are essential for accurate part identification and placement. Robots need to accurately identify and locate different components, regardless of their orientation or position. Advanced computer vision is needed to handle the variation in materials and lighting conditions.

-

Sensor Technology: Precise sensor technology is vital for monitoring robotic actions and ensuring accurate assembly. Force sensors, proximity sensors, and vision systems work in concert to guide the robot’s movements and ensure that components are properly aligned and fastened. Improving sensor accuracy is crucial for better robotic performance.

-

Robotic Programming: Programming robots for shoe assembly is exceptionally complex and time-consuming, requiring specialized expertise. The development of more intuitive programming interfaces and automated programming tools is necessary to reduce the costs and time associated with programming and maintaining robotic systems in a shoe factory.

Economic and Logistical Barriers to Robotic Nike Shoe Production

Beyond the technological challenges, significant economic and logistical barriers hinder the widespread adoption of robotic systems in shoe factories. These issues include:

-

High Investment Costs: The initial investment required for robotic systems and their integration into existing factory infrastructure is substantial. This cost can be prohibitive for many shoe manufacturers, especially smaller companies. The cost-benefit analysis is critical in this adoption decision.

-

Return on Investment (ROI): The return on investment for robotic systems in shoe manufacturing can be lengthy, depending on factors like production volume, automation level, and labor costs. A comprehensive ROI analysis is needed to ensure profitability.

-

Labor Costs and Workforce Retraining: While robots can increase efficiency, they also displace workers. This displacement necessitates retraining programs for affected employees and strategic planning to manage the transition to a more automated workforce. Addressing workforce retraining is crucial for the successful implementation of robotic systems.

-

Factory Infrastructure: Existing shoe factories may not be equipped to accommodate robotic systems, requiring significant modifications and upgrades to the facility's infrastructure, including power supply, space, and safety features. This requires a careful assessment of the factory's capabilities and a plan to adapt the environment for robotic integration.

The Future of Robotic Nike Shoe Production

Despite the current challenges, the future of robotic Nike shoe production is promising. Several developments could pave the way for wider adoption:

-

Collaborative Robots (Cobots): The increasing use of cobots, robots designed to work safely alongside humans, will enhance efficiency and productivity without fully replacing human workers. Cobots can handle repetitive or dangerous tasks, leaving more complex or nuanced tasks to humans.

-

Advancements in AI and Machine Learning: Continuous advancements in AI and machine learning will lead to more dexterous and adaptable robots, improving their ability to handle the complexities of shoe assembly. This increased adaptability is key to handling diverse designs and materials.

-

Cost-Effective Robotics: As the technology matures, robotic systems will become more efficient and affordable, reducing the initial investment and improving the overall ROI. This will make robotic solutions more accessible to smaller manufacturers.

-

Smart Factories: Integration of robotic systems into smart factories, leveraging data analytics and Industry 4.0 principles, will further optimize production processes and improve overall efficiency. This interconnectedness can improve real-time decision-making.

Conclusion

The path to robotic Nike shoe production is undeniably challenging. The intricate nature of shoemaking, coupled with technological, economic, and logistical hurdles, presents a significant hurdle. However, ongoing advancements in robotics, AI, and related technologies are gradually addressing these challenges. The future likely lies in a collaborative approach, integrating human expertise with the capabilities of increasingly sophisticated robotic systems. The journey toward fully automated robotic Nike shoe production is ongoing, but the potential for innovation in this field remains significant. Continue exploring this evolving field to witness the innovations shaping the future of footwear manufacturing.

Featured Posts

-

Ukraine Conflict Kyivs Response To Trumps Peace Plan

Apr 22, 2025

Ukraine Conflict Kyivs Response To Trumps Peace Plan

Apr 22, 2025 -

Are Stock Investors Ready For More Market Volatility

Apr 22, 2025

Are Stock Investors Ready For More Market Volatility

Apr 22, 2025 -

Death Of Pope Francis At 88 A Legacy Remembered

Apr 22, 2025

Death Of Pope Francis At 88 A Legacy Remembered

Apr 22, 2025 -

Karen Read Murder Trials A Complete Timeline

Apr 22, 2025

Karen Read Murder Trials A Complete Timeline

Apr 22, 2025 -

A Pan Nordic Army Assessing The Contributions Of Sweden And Finland

Apr 22, 2025

A Pan Nordic Army Assessing The Contributions Of Sweden And Finland

Apr 22, 2025

Latest Posts

-

4 5

May 10, 2025

4 5

May 10, 2025 -

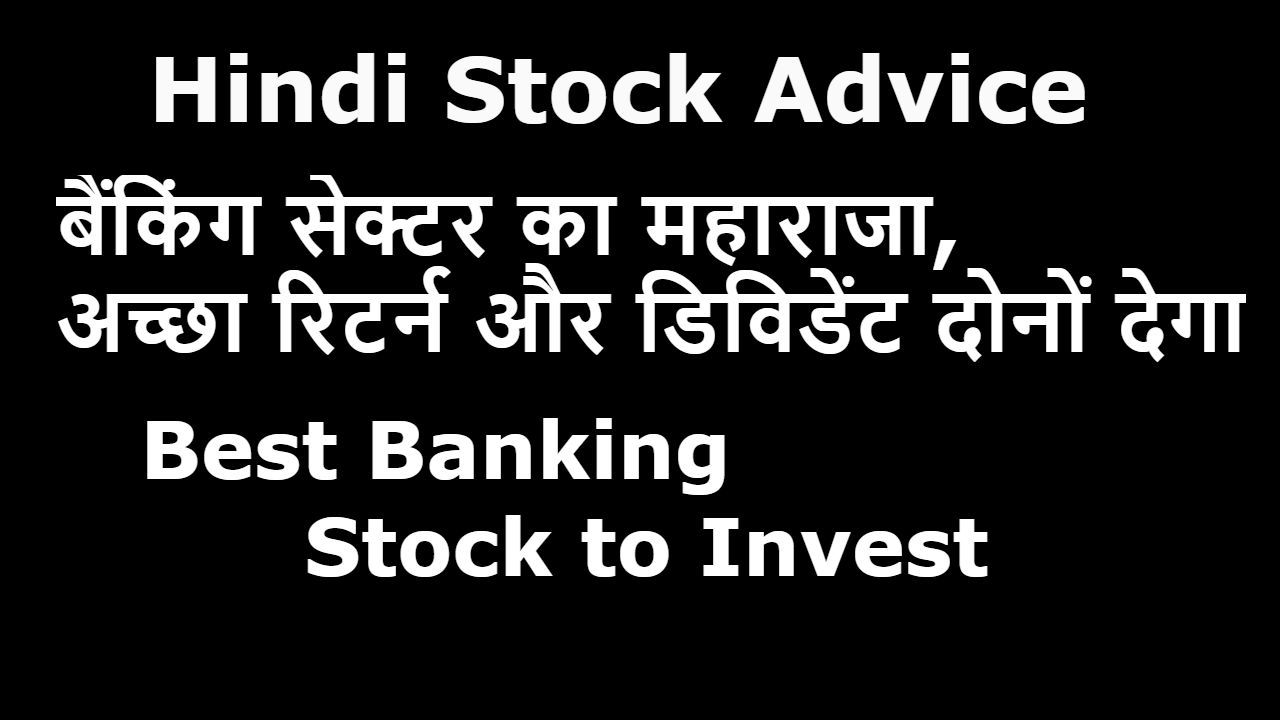

Analyzing Palantirs Potential A 40 Stock Increase By 2025 Is It Achievable

May 10, 2025

Analyzing Palantirs Potential A 40 Stock Increase By 2025 Is It Achievable

May 10, 2025 -

Late To The Game Evaluating Palantir Stock Investment Potential In 2024 For 2025 Gains

May 10, 2025

Late To The Game Evaluating Palantir Stock Investment Potential In 2024 For 2025 Gains

May 10, 2025 -

40 Palantir Stock Growth By 2025 A Realistic Investment Opportunity

May 10, 2025

40 Palantir Stock Growth By 2025 A Realistic Investment Opportunity

May 10, 2025 -

Should You Buy Palantir Stock Before Its Predicted 40 Rise In 2025

May 10, 2025

Should You Buy Palantir Stock Before Its Predicted 40 Rise In 2025

May 10, 2025